PRODUCT

High precision cnc lathe is a high precision and efficient automatic machine tool.

The cnc lathe manufacture is equipped with a multi-station turret or a power turret. The cnc lathe machine has a wide range of processing performance and can process complex workpieces such as straight cylinders, oblique cylinders, arcs, various threads, grooves, and worms.

Product Features

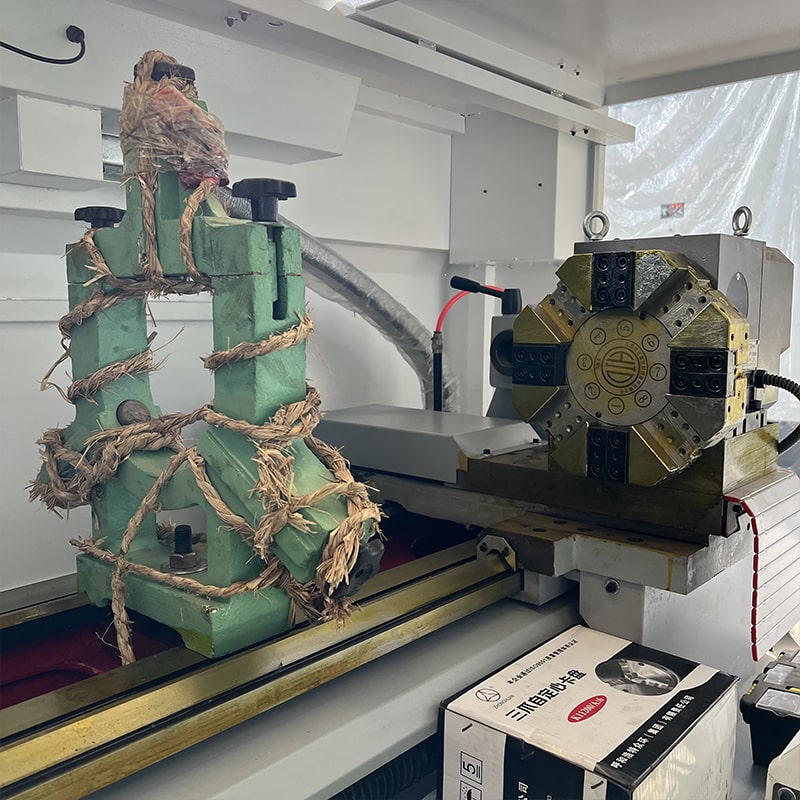

1. The mini cnc lathe machine adopts domestic or imported high-rigidity horizontal turret tool holder, which has high positioning accuracy and small deformation in heavy cutting.

2. The mini cnc lathe tool detection device can automatically input the tool tip position data into the numerical control system, greatly reducing the settling time when changing tools, and automatically compensating for tool tip wear.

3. The cnc mini metal lathe linear rolling guide meets the high-speed and high-efficiency requirements, reduces frictional resistance and temperature rise deformation, improves machining accuracy, and ensures long-term stability of cutting accuracy.

4. The lathe machine mini cnc adopts the overall inclined bed structure, which can still maintain the stability of the machine tool precision during heavy cutting.

5. The cnc mini metal lathe machine adopts full guide rail protection, and the cooling box and chip conveyor are separated from the main machine to ensure that the accuracy of the machine tool is not affected by thermal cutting.

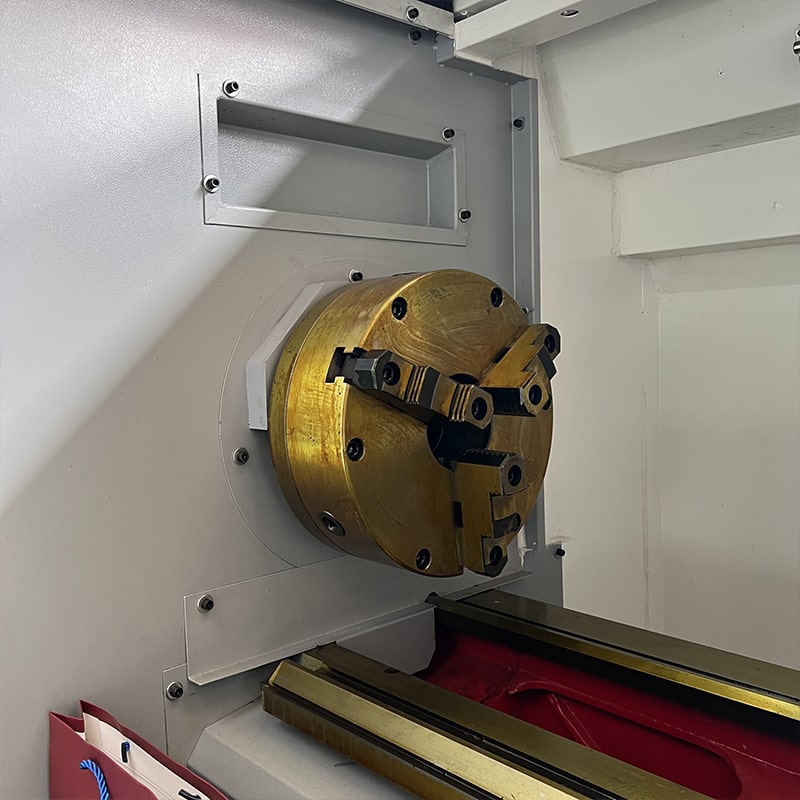

6. The CNC lathe turning headstock takes corresponding measures to reduce the thermal deformation of the spindle, so that the spindle can be kept relatively stable when the spindle works for a long time.

Application range of mini CNC lathe machine:

CNC lathe fanuc is aimed at processing cylinder blocks, cylinder heads, gearbox casings, etc., as well as multi-variety batch shells and box parts in the automotive, home appliance and other industries.

Video

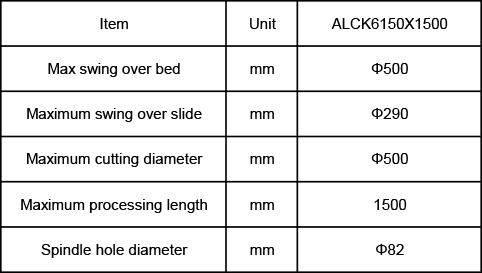

Product Parameters