PRODUCT

Cnc mini metal lathe machine is suitable for processing copper, aluminum, iron, plastic and other precision parts.

Lathe machine mini cnc is suitable for processing small parts in batches in industries such as instruments, automobiles, motorcycles, stationery, hardware and bathroom, military, etc., especially more complex parts.

Product Features

1.When processing a new workpiece on the metal flat bed cnc lathe machine, you only need to reprogram the processing program of the new workpiece to realize the processing of the new workpiece.

2.Metal cnc lathe machine can be matched with the high-precision control of the control system in order to adapt to high-precision processing.

3.Metal cnc lathe also has structural features such as sufficient processing and cooling, and tight protection. It is in a fully closed or semi-closed state during automatic operation.

4.The cnc lathe machine is also equipped with an automatic chip removal device.

What are the application fields of CNC lathes?

Cnc mini metal lathe can process some high precision and high work efficiency; using mini cnc lathe, we can process some kinds of spare parts in the industry: Such as electronic cigarette accessories, lighting accessories, electronic components and other hardware parts processing.

The shape of these mechanical parts is also a relatively complicated structure, but they can be processed by mini cnc lathe machine, and the products processed by cnc lathe are high-precision parts, which can fully meet the needs of these industries.

The cnc lathe machine has the characteristics of automatic processing and fast processing speed. Complex parts can be processed and formed at one time. The processing accuracy of cnc lathe manufacture is accurate and reliable, and the high precision cnc lathe can automatically feed materials, automatically stop when the materials are finished, and have high production efficiency.

Video

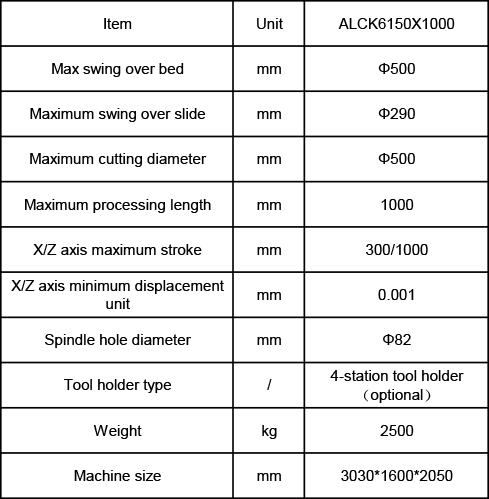

Product Parameters