PRODUCT

CNC vertical machining center ALVMC1160 is an advanced machining equipment featuring high efficiency, high precision and multiple functions. CNC metal milling machine is widely used in various industries, bringing significant production advantages and competitiveness to enterprises. This article will discuss the key features of the ALVMC1160 CNC metal milling machine and its application in manufacturing.

ALVMC1160 CNC milling machine metal has high-efficiency production capacity. CNC milling machine metal adopts advanced numerical control technology and automatic process flow, and has functions such as quick tool change, automatic loading and unloading and high-speed cutting. These features greatly improve production efficiency and work efficiency, and reduce the time and labor intensity of manual operation. The high rigid structure and stable performance of ALVMC1160 CNC milling machine metal guarantee the precision and processing quality under high-speed cutting.

ALVMC1160 Vertical CNC milling machine has high precision machining capability. The Vertical CNC milling machine is equipped with a precise servo system and advanced control technology, capable of achieving micron-level machining accuracy. Whether processing parts, complex contours or curved surfaces, ALVMC1160 can guarantee high-precision processing results. This makes Vertical CNC milling machines widely used in fields such as mold making, aerospace, automotive industry and medical equipment.

In addition, ALVMC1160 High precision CNC machining center has multi-functional machining capabilities. The High precision CNC machining center can perform routine machining operations such as milling, drilling, and boring, as well as special machining operations such as complex surface machining, threading, and chamfering. The multi-axis control system and flexible processing capability of ALVMC1160 Large CNC machining center make it suitable for processing various workpieces, providing enterprises with more processing options and flexibility.

Video

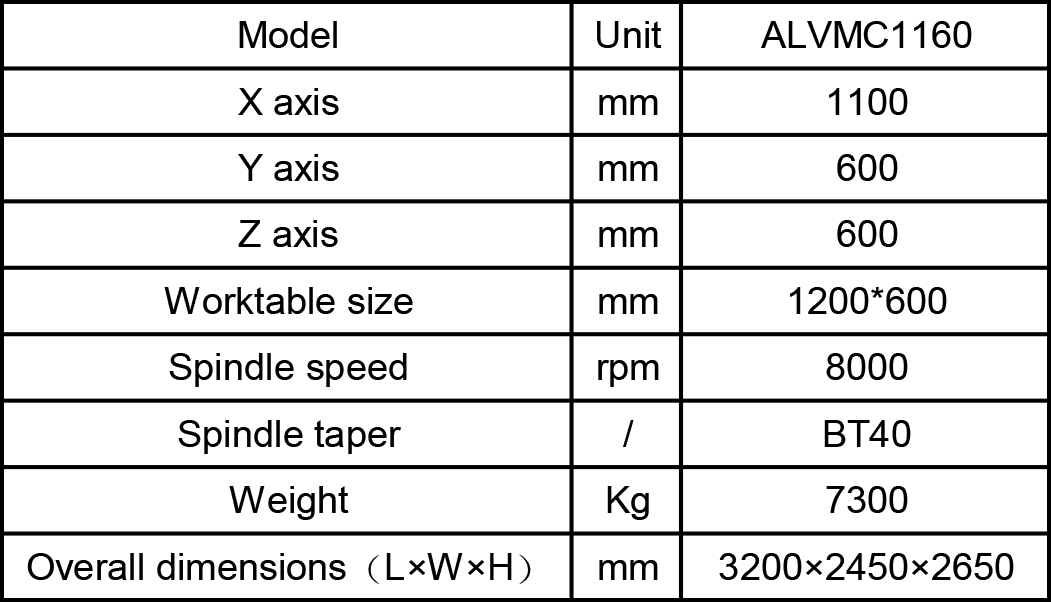

Technical Parameters