PRODUCT

Efficient and precise, shaping the future of industry——Vertical Machining Center ALVMC1160

Brand - ALLESCNC

Model - VMC1160

Dimensions - 3200x2450x2650mm

Price - $31,700(Standard Edition)/$33,200(Pro Edition)

Availability - 400 pieces of inventory available for sale every month

Certification - Meeting CE Standards in Terms of Quality & Safety

Payment Method - T/T/ Credit Cards

One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

The vertical machining center ALVMC1160 has become an ideal choice for many industries such as mold manufacturing, parts processing, and aluminum alloy processing due to its high efficiency and precision. CNC milling machines are widely used, which promotes the development of industrial manufacturing in a more efficient and precise direction. Whether it is mass production or customized processing, ALVMC1160 CNC milling machine is capable of all kinds of processing tasks, shaping the future of industrial manufacturing.

Main features of vertical machining center ALVMC1160:

1. High-speed and high-precision: ALVMC1160 vertical machining center adopts advanced numerical control technology and high-performance spindle, and has high-speed and high-precision processing capabilities. Its fast cutting and precision machining can meet the manufacturing needs of complex workpieces and improve production efficiency.

2. Large workbench: ALVMC1160 vertical machining center is equipped with a spacious workbench area, which is suitable for processing large workpieces, such as molds and parts. The large worktable provides more processing space, which makes the processing range wider and meets the processing needs of workpieces of different sizes.

3. Multi-axis machining: The vertical machining center can be equipped with a four-axis or five-axis system to realize multi-face machining of complex parts. Multi-axis machining improves the flexibility and precision of machining, and provides more possibilities for manufacturing complex parts.

4. Automation function: ALVMC1160 CNC milling machine is equipped with intelligent automatic tool changing system and workpiece measuring device to realize automatic production. An automatic tool change system drastically reduces tool change time and increases productivity, while workpiece measuring devices ensure consistent and precise machining.

5. Flexible and diverse: ALVMC1160 CNC milling machine supports a variety of processes and processing methods, and can be flexibly customized according to different application requirements. Whether it is mass production or small batch of diverse production tasks, ALVMC1160 CNC milling machine can do it.

Application of vertical machining center ALVMC1160 in multiple industries:

1. Mold manufacturing: In the mold manufacturing industry, ALVMC1160 high-precision vertical machining centers are widely used. The high-precision vertical machining center can efficiently process various molds, including plastic injection molds, die-casting molds, forging molds, etc. Its high precision and stability ensure that the molds are dimensionally accurate and have excellent surface quality.

2. Parts processing: ALVMC1160 high-precision vertical machining center is widely used in parts processing industry, including automobile, aviation, aerospace and other fields. High-precision vertical machining centers can efficiently process various metal parts, such as engine parts, chassis parts, aerospace structural parts, etc.

3. General machining: In addition to mold manufacturing and parts processing, ALVMC1160 high-precision vertical machining center is also suitable for various general machining tasks, such as milling, drilling, boring, etc., providing solutions for the processing needs of various workpieces.

4. Aluminum alloy processing: ALVMC1160 vertical machining center is also widely used in the field of aluminum alloy processing. Due to the light weight and high strength of aluminum alloy, in aerospace, automobile and other industries, ALVMC1160 vertical machining center is often used to process aluminum alloy parts.

5. Die processing: In the field of die processing, ALVMC1160 vertical machining center can be used to manufacture various types of dies, including gravure printing dies, letterpress printing dies, etc.

Machine standard and optional:

(1) Resin sand castings, tempered and aged.

(2) Taiwan Shangyin ball screw and precision screw lock nut;

(3) Taiwan Silver Roller Linear Guide

(4) Taiwan BT40 spindle unit (8000 rpm).

(5) Taiwan supporting booster cylinder and synchronous pulley.

(6) Imported NTN bearings for screw rods

(7) Inner protection of X, Y, Z three-axis stainless steel guide rails

(8) Equipped with automatic lubricating system, cooling, spindle air blowing, warning lights, explosion-proof lighting, etc.

(9) The standard configuration is full metal outer protection, and the economical half protection is optional.

(10) The system is equipped with a wide digital bus system as standard, and supports optional four-axis.

(11) Choose to configure the new generation,KND, Fanuc, Siemens, Mitsubishi and other systems.

Video

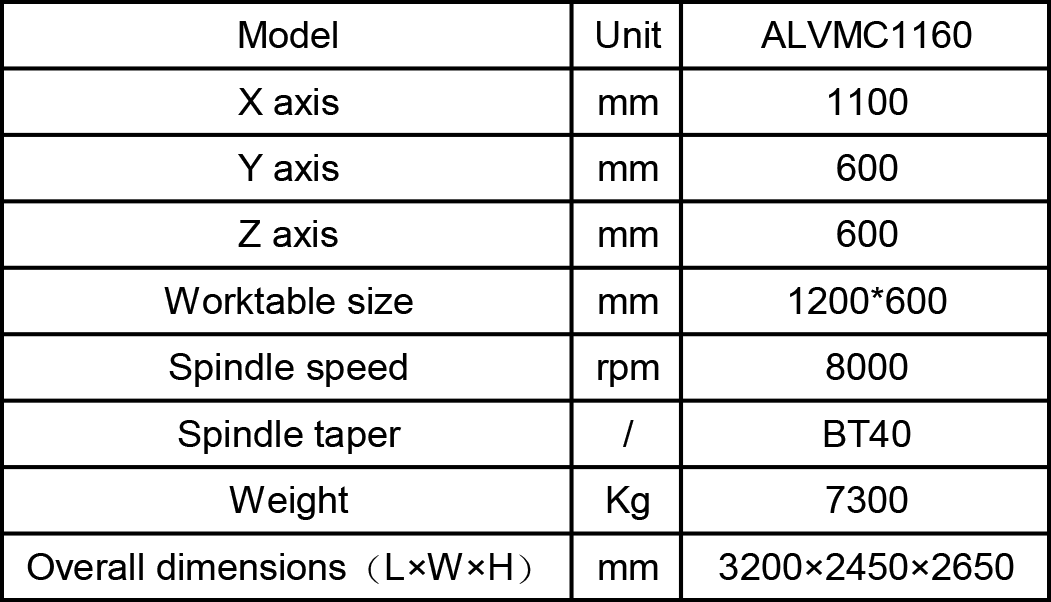

Technical Parameters