PRODUCT

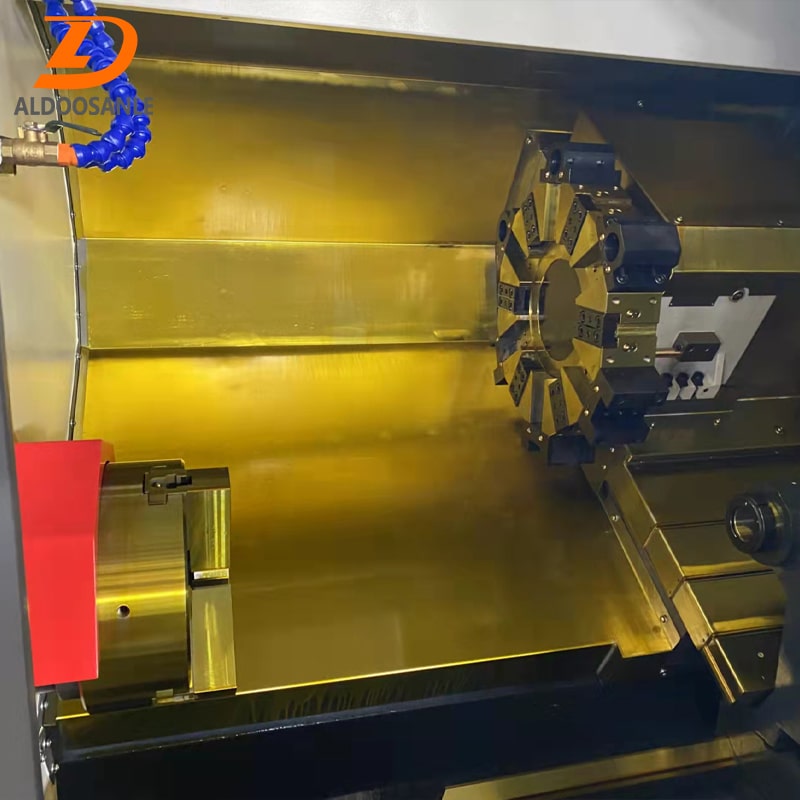

The cnc lathe can program the material or workpiece, the metal cnc lathe holds the material or workpiece in place and is rotated by the spindle. Cutting tools are mounted on different axes and move to engage workpieces for facing, turning, drilling or tapping operations.

High precision cnc lathe can be used to manufacture a variety of different parts including gears, shafts and spindles. CNC lathe manufacture can also be used to create threads and other types of surface treatments on metal parts.

Aldoosanlecnc Product Features

1. Increased Accuracy - With CNC turning, operators can achieve greater accuracy than traditional methods. This is because the cnc lathe machine is able to follow very precise instructions.

2. Repeatability - cnc lathe can produce the same parts over and over with little change. This is ideal for companies that need to produce large numbers of identical parts.

3. Increase productivity - the mini cnc lathe machine can work faster than human operators, which means more parts can be produced in less time.

Application of aldoosanlecnc cnc lathe machine

The mini cnc lathe machine slowly cuts material from the workpiece, resulting in precise finished or intricate parts. Many industries such as automotive, electronics and aerospace use these machines due to their flexible equipment.

cnc lathe machining can produce flat and threaded parts. In the case of an alloy wheel cnc lathe, a machine shop can produce 3-dimensional parts, the complexity of which varies greatly depending on how the cnc lathe for sale is constructed.

cnc lathe turning is very accurate for both small and large workpieces. Typically, the workpiece maintains its position in a single or CNC turning center. If necessary, the machinist can also install collets or clamps to hold the workpiece.

Video

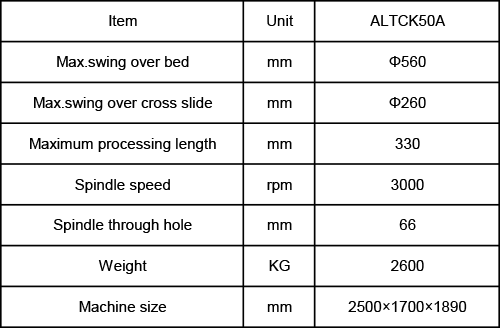

Product Parameters