PRODUCT

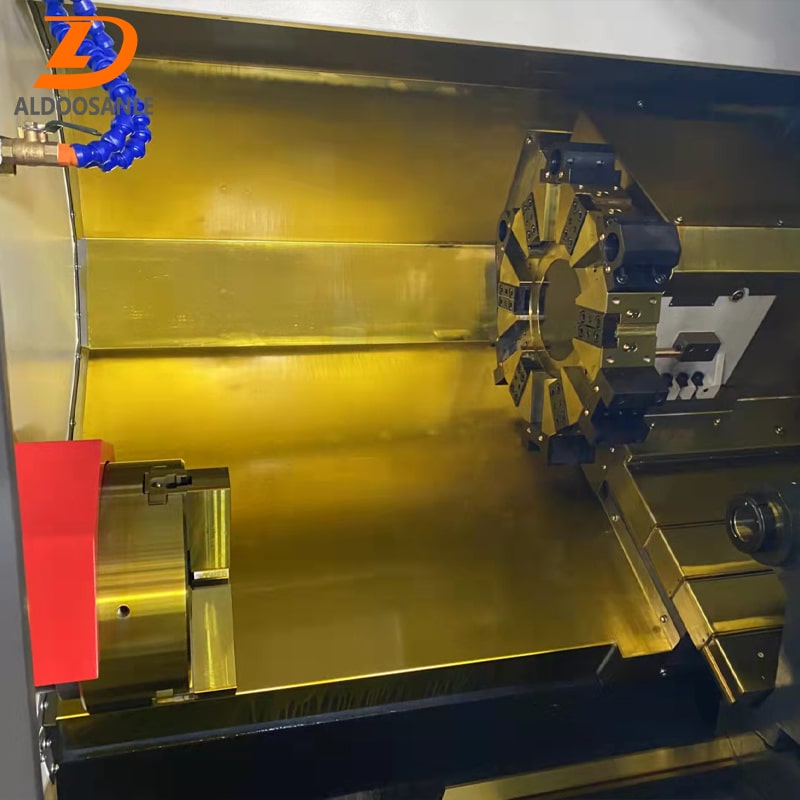

CNC lathe machine slant bed is a cnc lathe with 30 degree inclined guide rail. High precision cnc lathe is characterized by high precision, high speed and high spindle speed. Metal cnc lathe machine is widely used in the processing of medium-sized parts such as aviation, electronics, glasses, and lighters. The accuracy of cnc metal lathe machine can reach plus or minus 0.005. The cnc lathe machine slant bed adopts hard guide rails, speed change mechanisms and hydraulic clamps, and is an irreplaceable medium-sized part in the market.

Product Features

High machining accuracy:

The drive screw of high precision cnc lathe is a high-precision ball screw. The transmission clearance between the lead screw and the nut is small, but not without clearance. As long as there is a gap, when the screw moves in one direction and then drives in the opposite direction, backlash will inevitably occur, which will affect the repeatability of the CNC metal lathe machine and the machining accuracy.

The layout of the slant bed cnc lathe machine directly affects the play of the ball screw in the X direction, while the gravity directly affects the axial direction of the screw, so that the backlash during the transmission is almost zero.

The x-direction lead screw of the flat bed cnc lathe machine is not affected by the axial gravity and cannot directly eliminate the clearance.

This is the innate precision advantage brought by the design of the cnc slant bed lathe machine.

Product application

CNC lathe slant bed machine can process car & motorcycle & bicycle parts, we can customize these parts according to your drawings, welcome to send your drawings and get a free quote.

Video

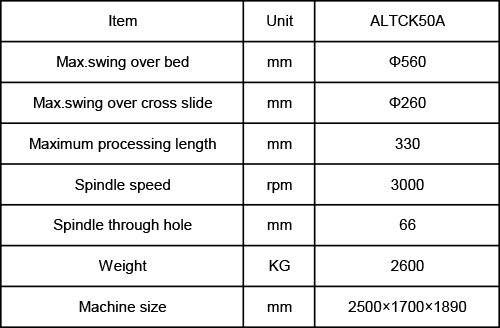

Product Parameters