PRODUCT

CNC lathe machine slant bed ALTCK36A can process auto parts

Metal cnc lathe machine is mainly used to process shafts, disks, sleeves and other workpieces with rotating surfaces, and is the most widely used type of machine tool processing in machinery manufacturing and repair factories.

The cnc lathe machine is mainly used for the processing of the rotary surface, such as cylindrical surface, conical surface, arc surface, thread, grooving and other cutting processing.

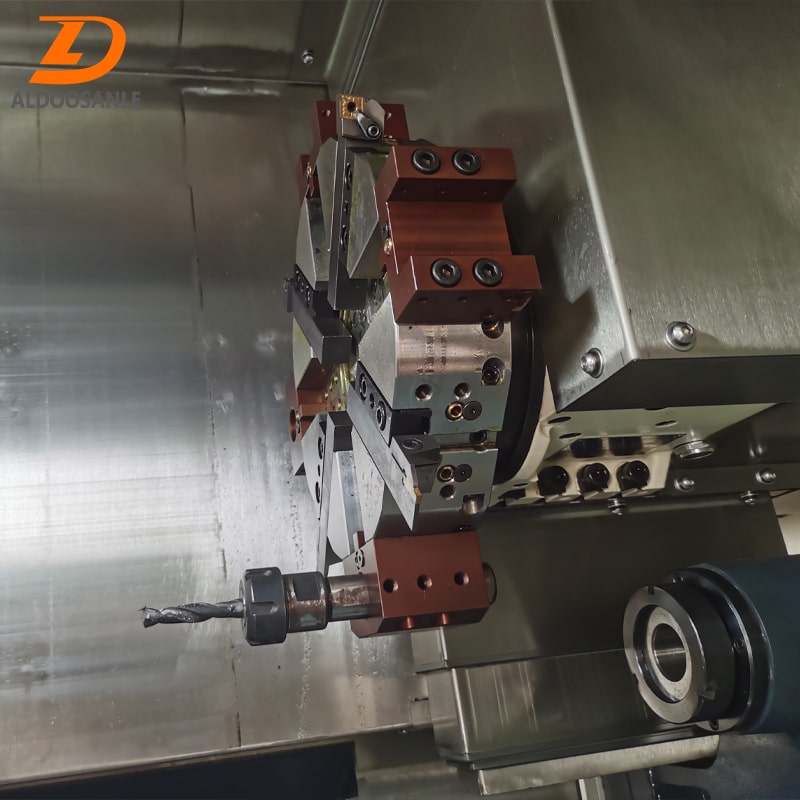

Therefore, the tools for CNC lathe can be divided into outer circle turning tools, inner hole turning tools, thread turning tools, grooving tools and other types.

Product Features

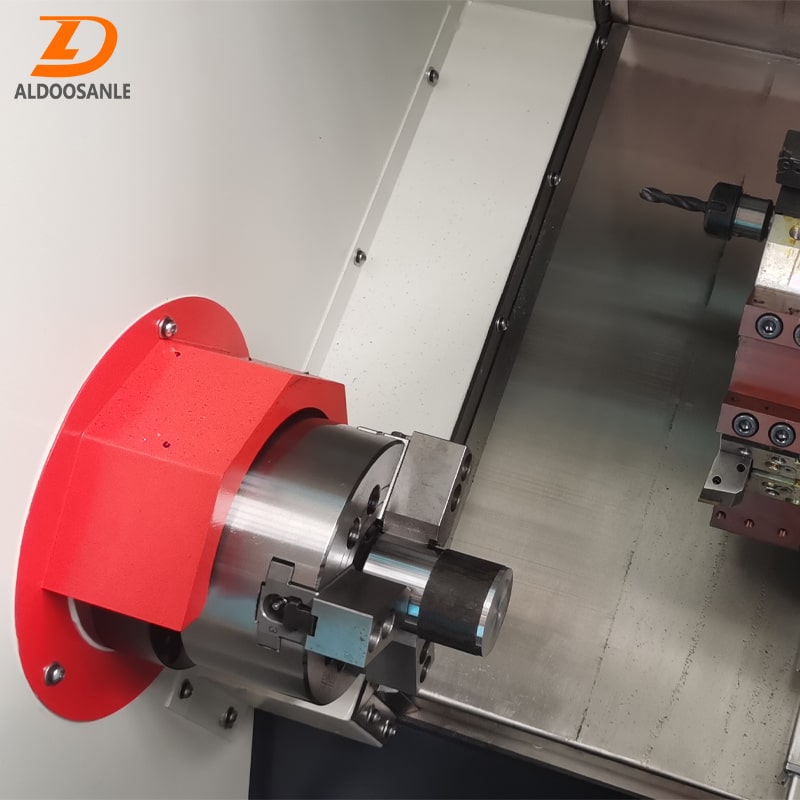

1. The slant bed cnc lathe machine uses a solid base plus scientific rib reinforcement, which has the greatest stability when turning.

2. The high-speed rotation of the spindle of the cnc slant bed lathe machine ensures fast and efficient processing, as well as very fine finishing of the workpiece.

3. The cnc lathe slant bed machine adopts super audio frequency quenching track, which makes it have good rigidity and stability. It can complete the processing of copper, aluminum, steel and other materials.

4. The surface of the X-axis and Z-axis ultra-wide box-shaped channel of cnc lathe machine slant bed is quenched and precision ground.

5. The 45 inclined bed design of the metal cnc lathe machine provides a very strong support for the turret and improves the efficiency of chip removal.

Video

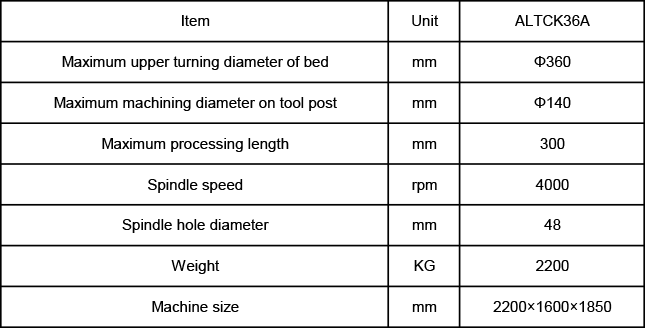

Product Parameters