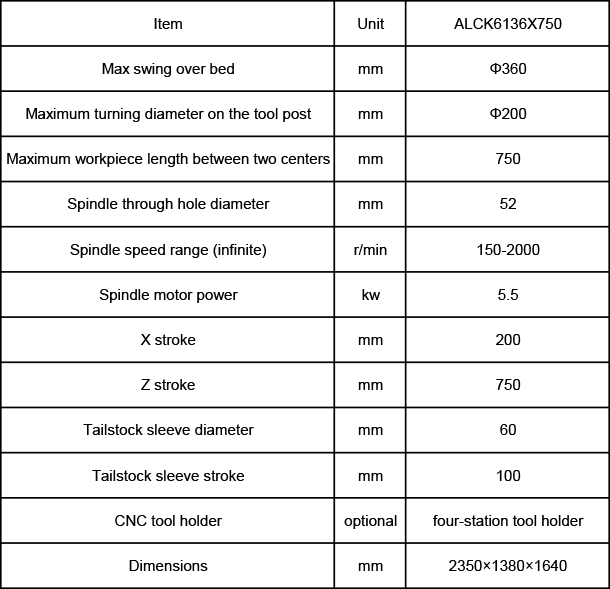

PRODUCT

Mini cnc lathe machine is an effective way to solve the problems of variable variety of parts, small batches, complex shapes and high precision, and to realize high-efficiency and automatic processing.

The positioning accuracy and repetitive positioning accuracy of cnc lathe machine are very high. As long as the process design and program are correct and reasonable, coupled with careful operation, the parts can be guaranteed to obtain high processing accuracy.

Product Features

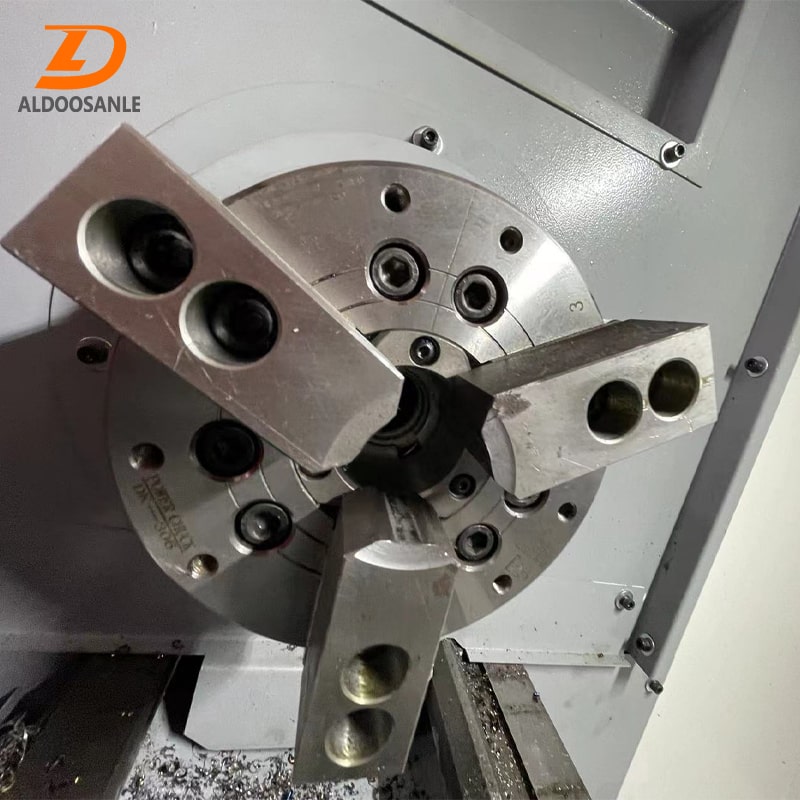

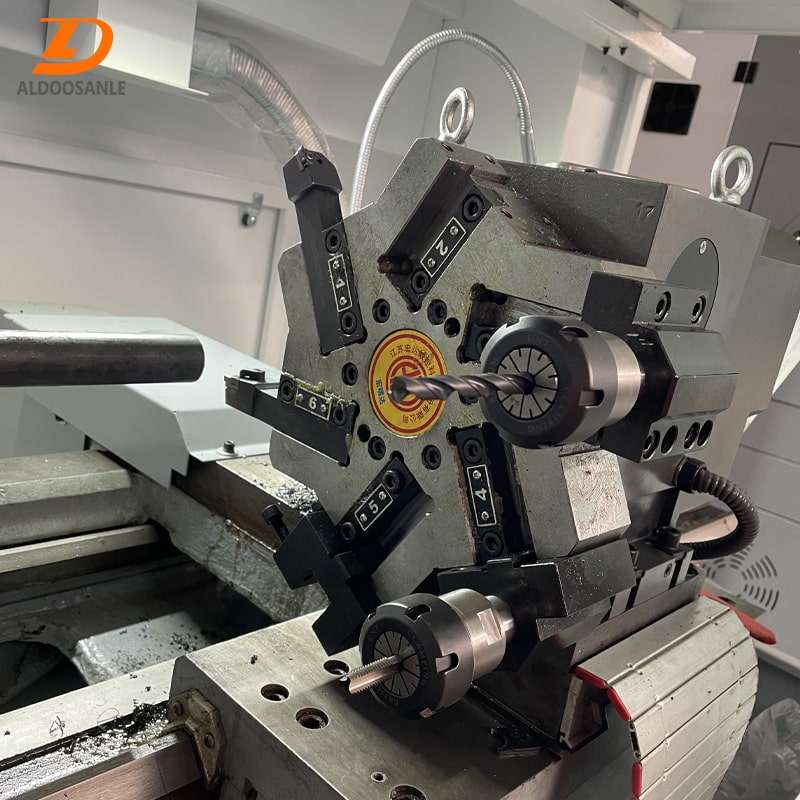

1. Cnc lathe turning greatly reduces the number of tooling, and complex tooling is not required for processing parts with complex shapes.

If you want to change the shape and size of the part, you only need to modify the flat bed cnc lathe part processing program, which is suitable for new product development and modification.

2. The processing quality of cnc lathe machining is stable, the processing accuracy is high, and the repetition accuracy is high, which is suitable for the processing requirements of aircraft.

3. The production efficiency is higher in the case of multi-variety and small batch production, which can reduce the time for production preparation, cnc lathe machine adjustment and process inspection, and reduce the cutting time due to the use of the optimal cutting amount.

4. Metal cnc lathe can process complex profiles that are difficult to process by conventional methods, and can even process some unobservable processing parts.

Application industries of flat bed cnc lathe machine:

The parts processed by Horizontal cnc lathe include the overall wall panels, girders, skins, bulkheads, propellers of aircraft and rockets, and mold cavities of casings, shafts, discs, and blades of aero-engines.

Any plane curve can be approximated by a straight line or an arc, and the mini cnc lathe machine has the function of arc interpolation, which can process various parts with complex contours.

Video

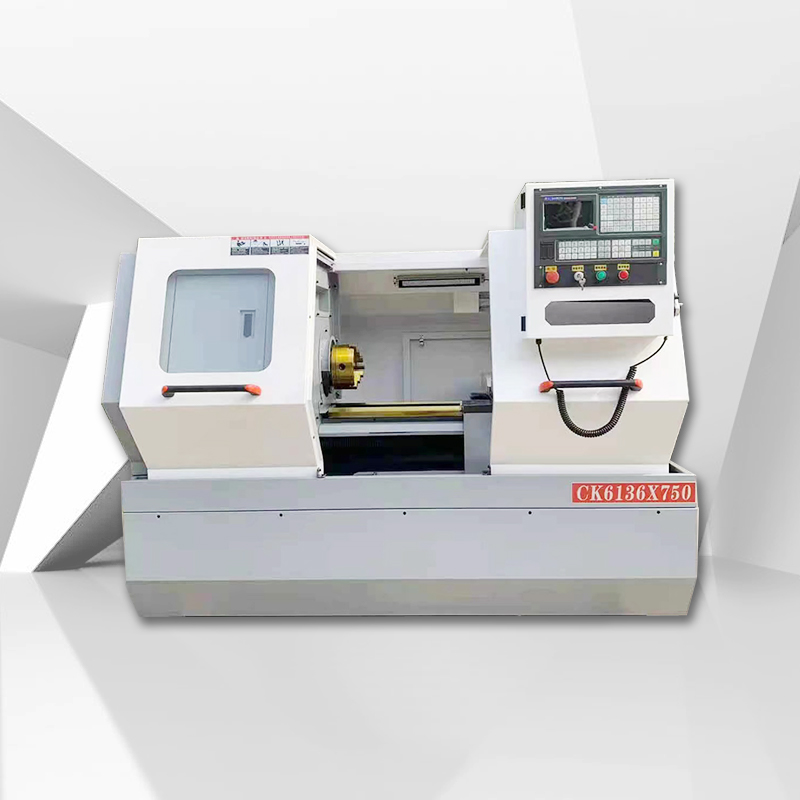

Product Parameters