PRODUCT

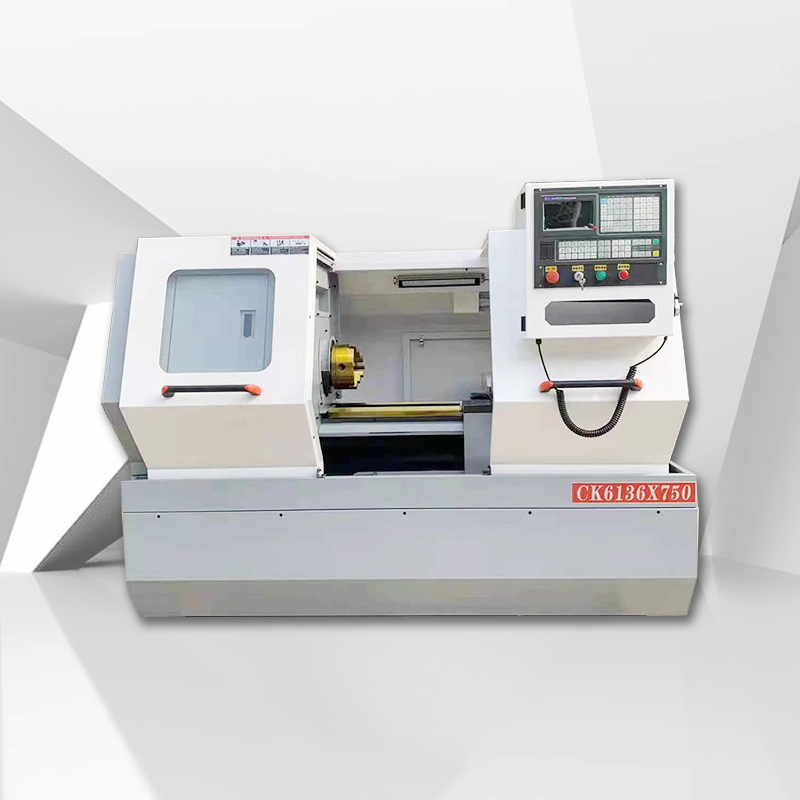

CNC Horizontal Lathe ALCK6136 metal lathe machine

CNC Lathe Flat Bed can process parts with complex structure of square and round combination. High Precision CNC Lathe is an effective way to solve the problems of variable variety of parts, small batches, complex shapes and high precision.

High precision cnc lathe automatically completes multi-process processing of small and medium-sized workpieces according to the set program. It can automatically load and unload materials, and process a batch of the same workpieces repeatedly. It is suitable for mass production.

Product Features

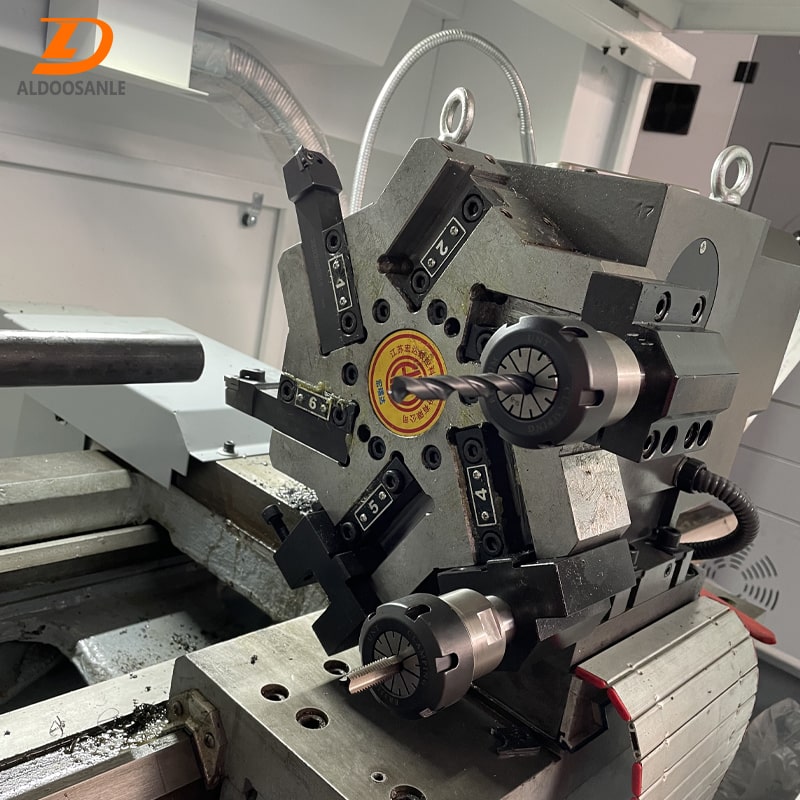

1. The transmission chain is short: the movement of the high precision cnc lathe tool holder in two directions is driven by two servo motors.

The servo motor is directly connected with the lead screw to drive the movement of the tool rest. The servo motor and the lead screw can also be continuously changed according to the control command, and there is no need to use a multi-stage gear pair to change the speed between it and the main shaft.

With the development of the motor wide speed regulation technology, the goal is to cancel the speed change gear pair, and at present it is necessary to change several speed ranges through the first gear pair.

Therefore, the structure inside the headbox is much simpler than that of a conventional lathe.

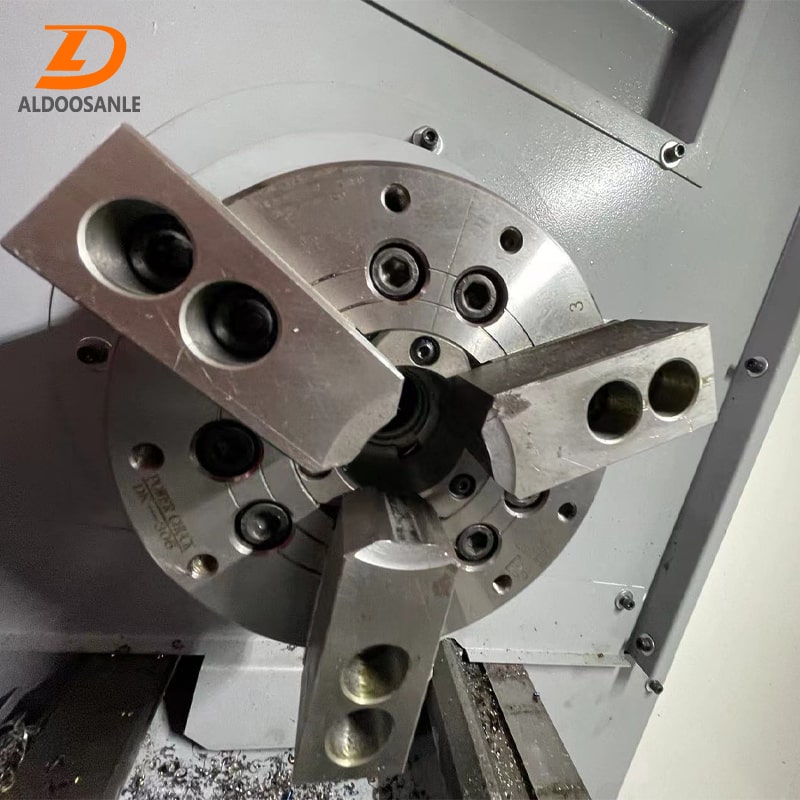

2. High rigidity: it matches the high-precision control of the control system, so as to adapt to high-precision processing.

3. Light drag: The movement of the tool rest generally adopts a ball screw pair. In order to drag the machine lightly, the lubrication of the flat bed cnc lathe machine is relatively sufficient, and most of them are automatically lubricated by oil mist.

Product application

1. CNC Lathe Machine Horizontal machining special-shaped parts, such as brackets, forks and other parts with irregular shapes, etc., most of which need to be mixed and processed by multiple stations.

2. Turning Machine CNC Lathe processes surface parts, and metal working lathe can complete the surface of parts composed of complex curves or curved surfaces.

3. CNC Lathe Machine Metal processes flat parts and parts with holes, and parts whose processing surface is parallel to the horizontal plane with the same angle are called flat parts.

4. CNC Lathe Machine Metal Horizontal processes variable bevel parts, and the parts whose included angle between the machining surface and the horizontal plane is continuously changing are called variable bevel parts.

Video

Product Parameters

| Item | Unit | ALCK6136 |

| Max swing over bed | mm | Φ360 |

| Maximum turning diameter on the tool post | mm | Φ200 |

| Maximum workpiece length between two centers | mm | 750 |

| Spindle through hole diameter | mm | Φ52 |

| Spindle speed range (infinite) | r/min | 150-2000 |

| Spindle motor power | KW | 5.5 |

| X stroke | mm | 200 |

| Z stroke | mm | 750 |

| Dimensions (length × width × height) | mm | 2350X1380X1640 |

Contact me for a detailed catalog and quote: https://wa.me/+8615564169508