PRODUCT

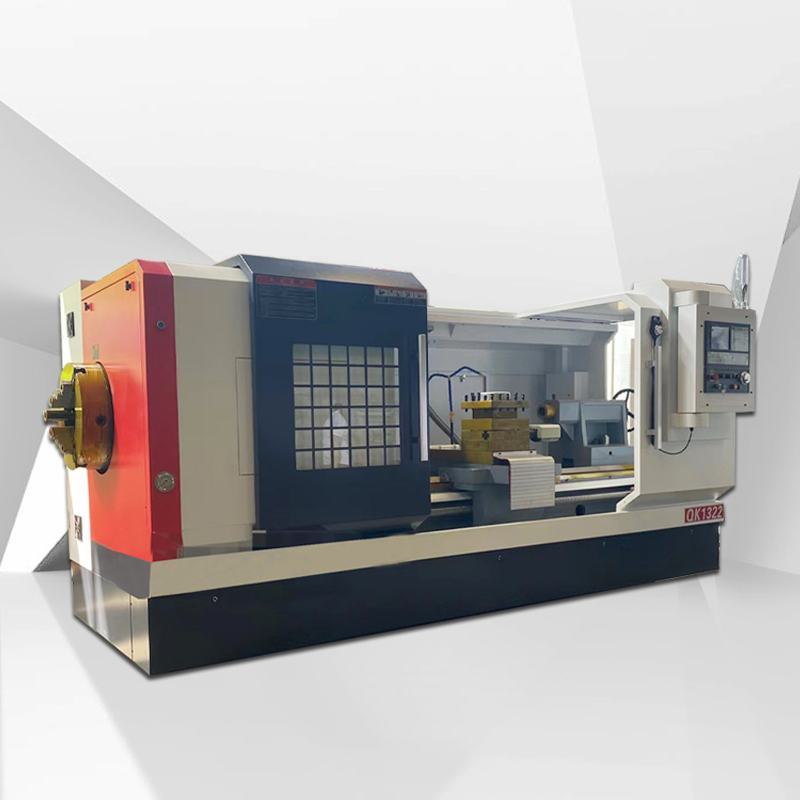

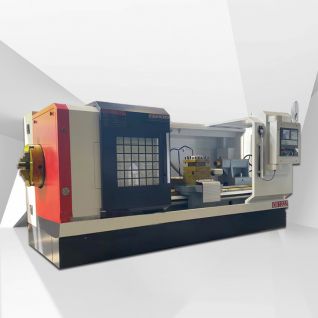

ALQK1322 CNC pipe thread lathe machine

Brand - ALLESCNC

Model - QK1322

Dimensions - 3750x1830x1900mm

Price - $27,900(Standard Edition)/$29,400(Pro Edition)

Availability - 400 pieces of inventory available for sale every month

Certification - Meeting CE Standards in Terms of Quality & Safety

Payment Method - T/T/ Credit Cards

One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

CNC pipe thread lathe ALQK1322 plays an important role in petrochemical, pipeline manufacturing and machinery manufacturing industries due to its high-precision processing capability, multi-functional processing capability, high-efficiency production capacity and stable performance. By selecting suitable optional configurations, the processing efficiency and processing quality can be further improved to meet the customized processing needs of different industries.

Features of CNC pipe thread lathe:

1.High-precision processing capability: ALQK1322 CNC pipe thread lathe adopts advanced CNC technology and precision transmission system, with excellent processing accuracy. It can realize the precision machining of pipe thread, ensuring the accuracy of workpiece size and the consistency of surface quality.

2.Multifunctional processing capability: ALQK1322 CNC pipe thread lathe can perform various processing operations, including turning, milling, drilling and so on. This makes it competent for a variety of workpiece processing needs, providing flexible and diverse processing solutions.

3.Efficient production capacity: The equipment is equipped with high-speed spindle and feed system to achieve fast processing speed and efficient production capacity. For the demand of mass production and short lead time, ALQK1322 can meet the high-efficiency production requirements.

4.Advanced CNC system: ALQK1322 CNC pipe thread lathe is equipped with advanced CNC system, with friendly operation interface and rich processing control functions. Operators can easily program and operate, realizing efficient production control and process management.

5.Stable performance: ALQK1322 CNC pipe thread lathe has stable and reliable performance, can run stably for a long time, and maintains the stability and reliability of processing quality. Its robust construction and high-quality components guarantee stable and precise machining processes.

Application industries of CNC pipe thread lathe:

ALQK1322 CNC Pipe Threading Lathe is widely used in many industries, including petrochemical, pipeline manufacturing, machinery manufacturing, etc. CNC oil thread lathes are mainly used for processing various pipeline threads, such as oil pipelines, natural gas pipelines, water pipelines, etc. In addition, CNC petroleum thread lathes can also be used to manufacture other workpieces that require precision pipe threads, such as valves, connectors, pipe fittings, etc.

Standard configuration of CNC pipe thread lathe ALQK1322:

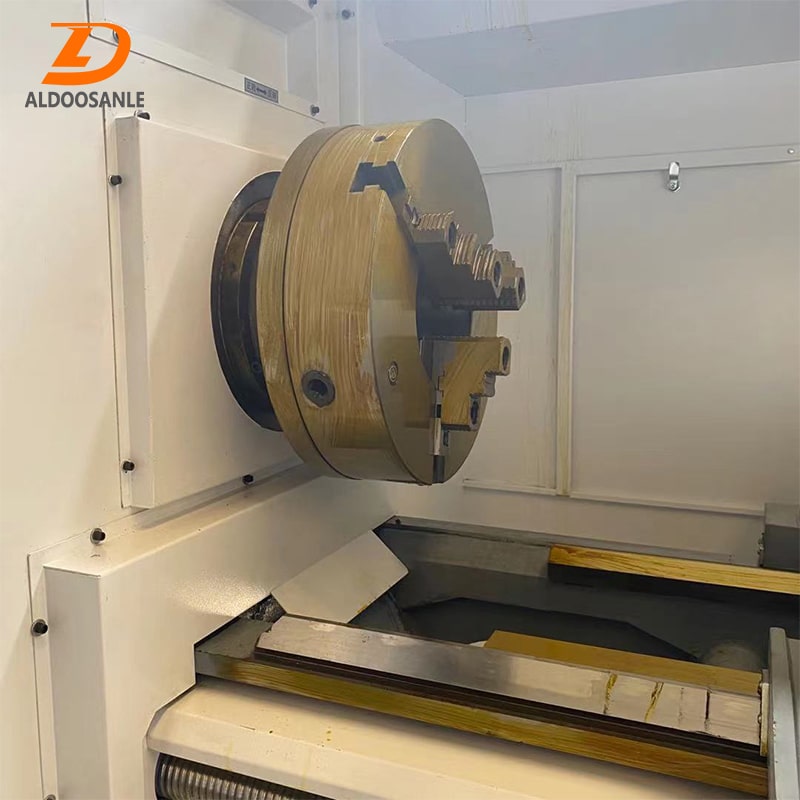

The standard configuration includes high-precision spindle, CNC system, feed system, automatic lubrication system, workpiece clamping device, etc. These standard configurations guarantee the basic functions and processing performance of ALQK1322.

In terms of optional configuration, according to customer needs, the following configurations can be selected:

1. Automatic loading and unloading system: realize automatic workpiece loading and unloading, improve production efficiency and operation convenience.

2. Workpiece measurement system: Equipped with a workpiece measurement device, it can automatically measure the size and shape of the workpiece to improve the control and consistency of machining accuracy.

3. Automatic tool change system: Equipped with an automatic tool change device to achieve fast and accurate tool change, improving production efficiency and processing flexibility.

4. Processing process detection system: Equipped with processing process monitoring device, it can monitor tool wear and workpiece deformation in real time, provide real-time feedback and adjustment, and ensure the stability of processing quality.

Video

Technical Parameters

|

Project |

Content |

Unit |

ALQK1322 |

|

Processing range |

Maximum turning diameter of bed |

mm |

Φ630 |

|

Maximum turning diameter on the skateboard |

|

Φ330 |

|

|

Maximum processing length |

mm |

1500 |

|

|

Maximum machining diameter |

mm |

Φ630 |

|

|

Maximum bar diameter |

mm |

Φ330 |

|

|

Spindle |

chuck |

|

Front and rear 500 four claws |

|

Spindle head form |

|

D11 |

|

|

Spindle through hole diameter |

mm |

Φ220 |

|

|

Spindle bore taper |

|

1:20 |

|

|

Spindle series |

|

Manual second gear |

|

|

Spindle speed range |

r/min |

25-89/108-382 |

|

|

feed |

X/Z axis travel |

mm |

350/1500 |

|

X/Z axis screw diameter × pitch |

mm |

φ3208/φ5010 |

|

|

X/Z rapid traverse speed |

m/min |

4/6 |

|

|

Tool holder form |

|

tool holder |

|

|

number of stations |

|

4 |

|

|

Tool Specifications: Turning/Boring |

mm |

32/40 |

|

|

tailstock |

Sleeve diameter/stroke |

mm |

Φ100/250 |

|

Sleeve inner hole taper |

|

MT6 |

|

|

Sleeve drive form |

|

manual |

|

|

Tailstock body movement form |

|

manual |

|

|

motor |

Spindle motor power |

Kw |

11 |

|

Spindle motor torque |

NM |

48 |

|

|

X/Z motor power |

Kw |

1.5/2.3 |

|

|

X/Z motor torque |

NM |

10/15 |

|

|

Cooling pump motor power |

W |

125 |

|

|

Others |

battery capacity |

KVA |

15 |

|

saddle layout |

|

flat bed |

|

|

Rail form |

|

Hard rail (greater than HRC50) |

|

|

Machine weight |

kg |

4200 |

|

|

Machine tool dimensions: length × width × height |

mm |

3750/1830/1900 |