PRODUCT

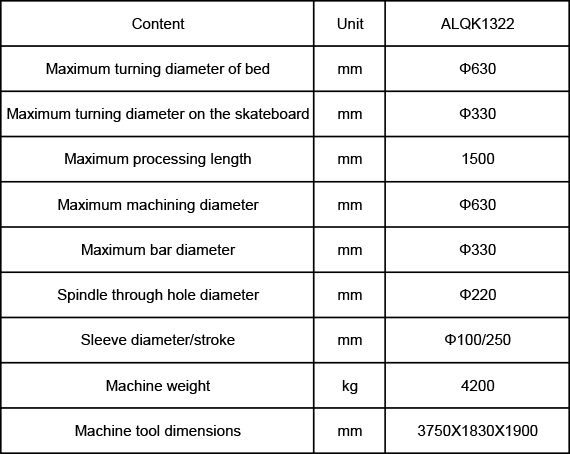

CNC pipe threading lathe ALQK1322 for petroleum equipment

Aldoosanlecnc CNC pipe thread lathe ALQK1322 is mainly used to process the internal and external threads of pipe tools, and also has the function of cnc lathe machine, which can process the outer circle, inner hole and end face of workpieces such as shafts and discs.

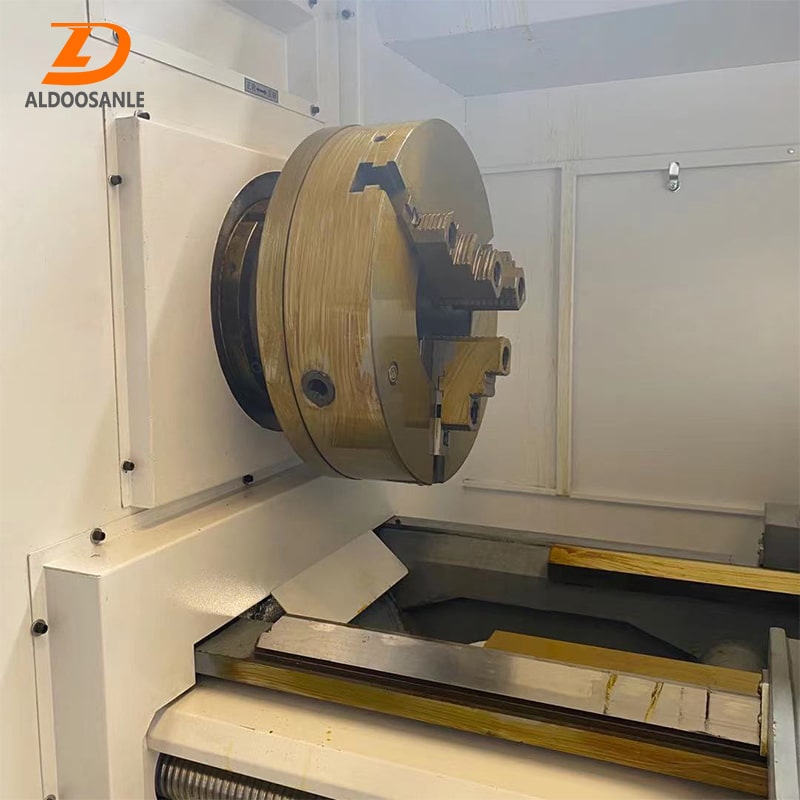

Aldoosanlecnc CNC pipe thread lathe ALQK1322 is a horizontal lathe specially designed for turning large diameter pipe fittings. The high quality cnc lathe automatic spindle has a relatively large through hole diameter (generally more than 135mm), and there are chucks on the front and rear of the spindle box. In order to facilitate the clamping and processing of large-diameter pipe fittings or rods.

Automatic CNC Pipe Threading Machine is widely used in machining operations in machinery manufacturing, petroleum, chemical, coal, geological exploration, urban water supply and drainage and other industries.

Product Features

1. The spindle of the cnc lathe pipe thread lathe machine has a large enough hole diameter, high passability, and stable workpiece clamping with double chucks.

2.CNC Oil Lathe overall body is cast by high-quality high-strength cast iron with very high precision.

3. The carriage of the CNC turning machine adopts the guide rail surface pasting process, which has good wear resistance and long service life.

4.With large power, it can be competent for heavy-duty and powerful cutting.

CNC pipe threading lathe machining environment

1. The CNC pipe thread lathe power supply is generally installed in the machining workshop. There are many electromechanical equipment in the workshop, resulting in large fluctuations in the power grid. Therefore, the location where the cnc lathe pipe thread lathe machine is installed requires strict control of the power supply voltage. Power supply voltage fluctuations must be within the allowable range and remain relatively stable. Otherwise, the normal operation of the CNC system will be affected.

2. The location of CNC Oil Lathe should be far away from the vibration source, avoid the influence of direct sunlight and thermal radiation, and avoid the influence of humidity and airflow.

3. The temperature of the CNC turning machine processing environment shall not be lower than 30 degrees Celsius, and the relative temperature shall be less than 80%. There is an exhaust fan or a cooling fan inside the CNC electric control box to keep the electronic components and the central processing unit working temperature constant. Excessive temperature and humidity will reduce the life of control system components and lead to increased failures.

Video

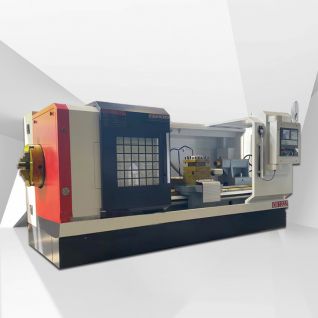

Technical Parameters