PRODUCT

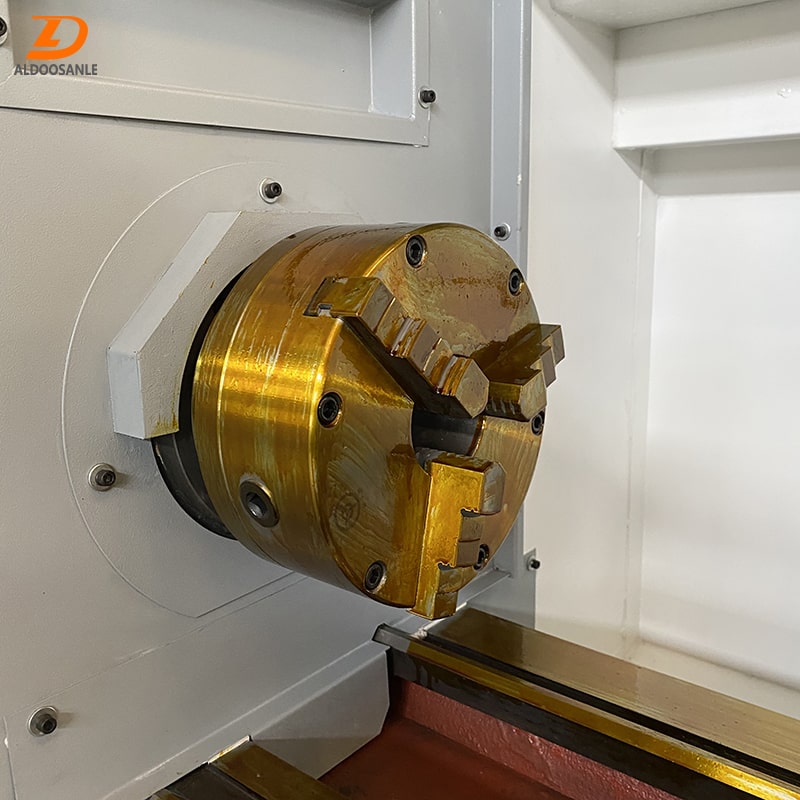

CNC lathe machine horizontal has high processing precision in the process of hardware processing, and has the characteristics of linear arc interpolation and automatic speed change, and its technical scope is much wider than that of ordinary machine tools.

Turning machine cnc lathe has high rigidity, high precision in manufacturing and tool setting, and can easily and accurately enter manual correction and automatic correction, so it can process parts that require dimensional accuracy.

Product Features

1.CNC lathe machine horizontal reduces processing time, thereby accelerating the turnover of working capital and improving economic benefits.

2.CNC lathe machine metal reduces the labor intensity of workers, especially when machining threads.

3. CNC lathe machine metal horizontal greatly improves productivity. Generally, a CNC lathe can improve the efficiency by 2 to 3 times than an ordinary lathe.

4. The machining accuracy of metal working lathe can be corrected and repaired by software, so it can obtain machining accuracy and repeatability higher than that of the machine tool itself.

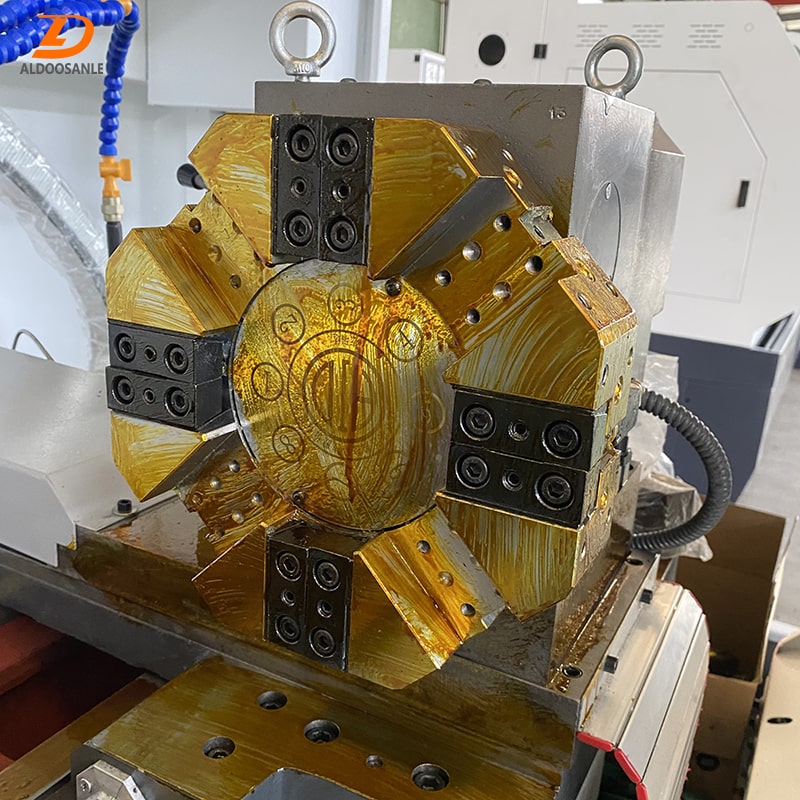

5.CNC lathe flat bed can complete the processing of complex-shaped shaft, sleeve and disc parts, and has a wide range of uses.

Product application

CNC flat bed lathe can produce a wide variety of spare parts used in the industry, such as electronic cigarette accessories, lighting accessories, electronic components and other hardware processing.

The shape of these mechanical parts is a relatively complex structure, but the horizontal lathe machine can produce some parts with good precision for the production needs of these industries.

Video

Product Parameters

| Item | Unit | ALCK6150X1000 |

| Max swing over bed | mm | Φ500 |

| Maximum swing over slide | mm | Φ290 |

| Maximum cutting diameter | mm | Φ500 |

| Maximum processing length | mm | 1000 |

| X/Z axis maximum stroke | mm | 300/1000 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ82 |

| Weight | KG | 2500 |

| Machine size | mm | 3030*1600*2050 |

Contact me for a detailed catalog and quote: https://wa.me/+8615564169508