PRODUCT

Features and applications of high-precision CNC turning and milling compound ALTCK550D

CNC machine tool technology plays an important role in modern manufacturing, providing efficient and high-precision processing solutions for various industrial fields. Among them, CNC turning and milling compound machine tool, as an advanced equipment integrating turning and milling functions, has significant advantages in improving production efficiency, reducing processing procedures and improving parts quality. ALTCK550D is a leading CNC turning and milling compound machine tool, its characteristics and application industry will be elaborated in this article.

As a high-precision CNC turning-milling machine tool, ALTCK550D has shown excellent application potential in aerospace, automobile manufacturing, mold processing and other industries due to its high precision, high efficiency, and flexibility. With the continuous development of manufacturing technology, ALTCK550D CNC turning and milling compound machine tool is expected to play an increasingly important role in promoting the further innovation and improvement of processing technology in various industries.

Features of ALTCK550D CNC lathe:

1.High-precision machining: ALTCK550D milling and turning is equipped with an advanced control system and high-precision sensors, which can achieve micron-level machining accuracy. Whether it is complex curved surface processing or precision parts processing, ALTCK550D can maintain stable processing quality.

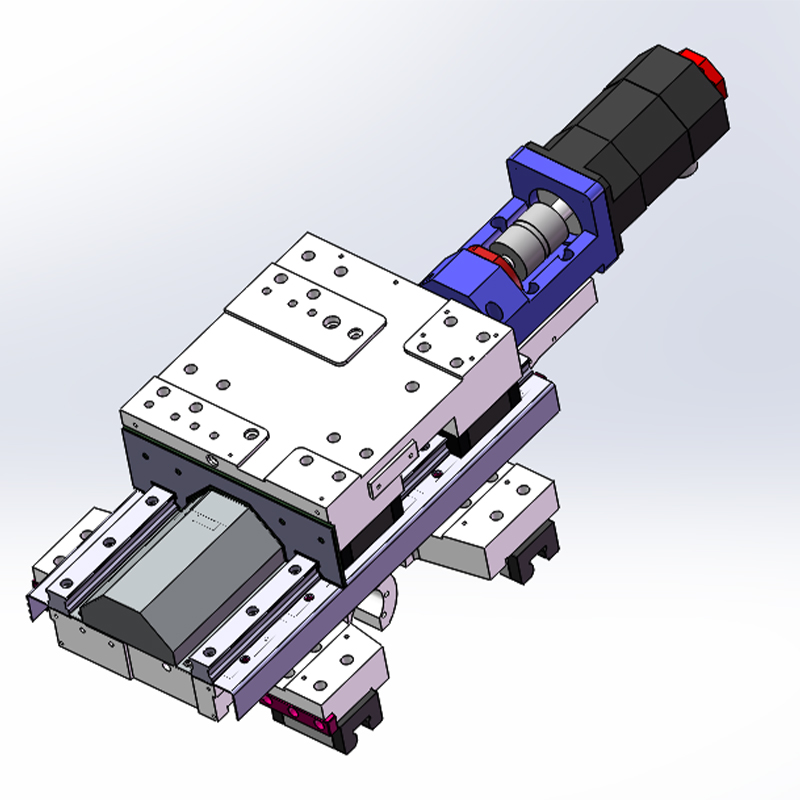

2.Composite processing function: Compared with traditional machine tools, ALTCK550D CNC turning and milling compound machine not only has turning function, but also integrates milling function, which realizes flexible switching of various processing methods on one machine tool, greatly saving production time and equipment cost .

3.High-efficiency production: ALTCK550D CNC turning and milling compound machine has a high degree of automation, equipped with automatic tool changer and workpiece measurement function, and can continue to process in an unattended state, thereby improving production efficiency and output.

4.Flexibility and adaptability: Machine tool operators can quickly adjust processing parameters and cutting paths through the control interface to adapt to different processing needs. This kind of flexibility makes ALTCK550D CNC turning and milling compound machine especially suitable for small batch and multi-variety production environment.

Application industries of ALTCK550D CNC turning and milling compound machine:

1.Aerospace: In the field of aerospace, complex aviation parts usually require high-precision machining, and the ALTCK550D CNC turning and milling compound machine can meet its strict requirements on processing quality and precision, such as engine parts, flight control components, etc.

2.Automobile manufacturing: Automobile manufacturing involves a large number of parts processing. The high efficiency and composite processing function of ALTCK550D CNC turning and milling compound machine make it an ideal choice for manufacturing engines, gearboxes, chassis and other components.

3.Mold processing: Mold manufacturing usually requires fine surface processing and complex part structure. The high precision and compound processing capability of ALTCK550D CNC turning and milling compound machine make it have a wide application prospect in the field of mold manufacturing.

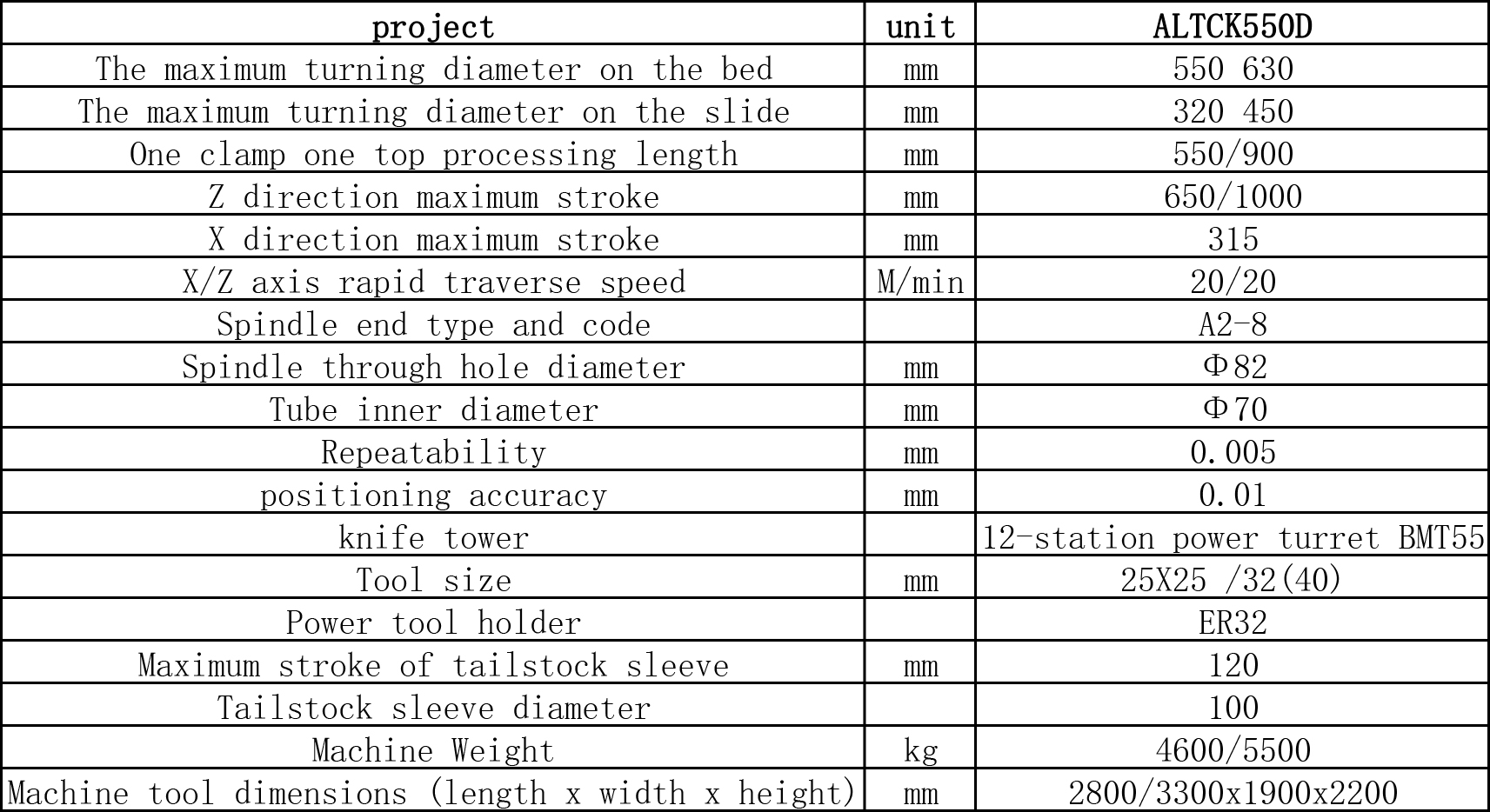

Technical Parameters