PRODUCT

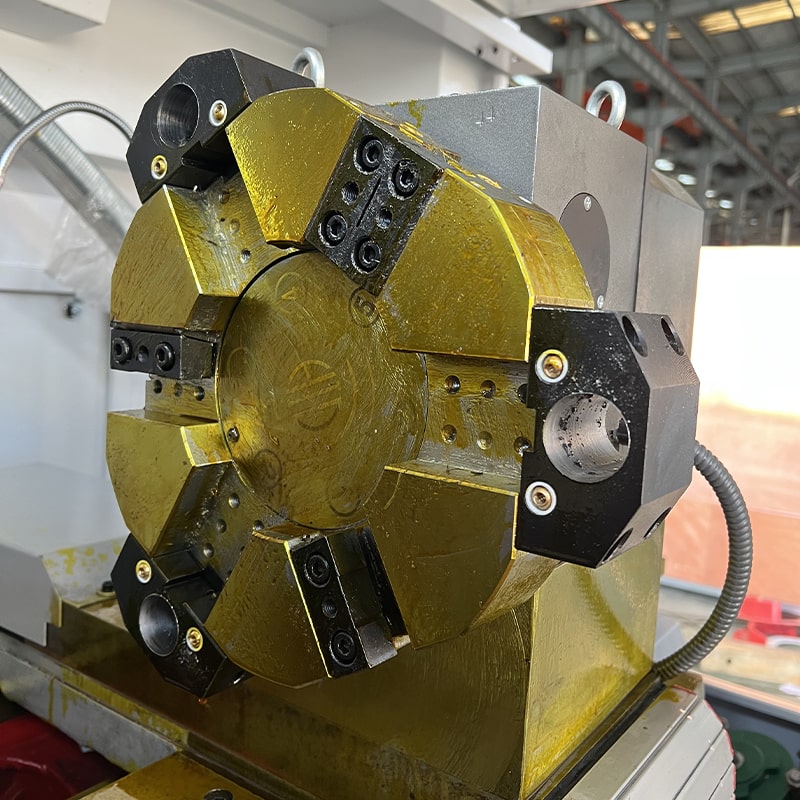

Cnc lathe turning can support a variety of specialized tools for turning that can be independently attached to the tool holder between cutting operations or controlled by the turret.

Depending on the number of machining axes of the cnc horizontal lathe, its tool can slide left and right, up and down, forward or backward along the length of the bed to perform the cutting operation.

Product Features

1.Mini cnc lathe can guarantee the precision of stainless steel parts, the cutting process is completely controlled by computer program, which reduces the chance of making mistakes during processing.

2. Cnc mini metal lathe can improve the surface roughness of stainless steel, and lathe machine mini cnc can improve the surface roughness of stainless steel parts.

3.Cnc mini metal lathe machine has no processing cost compared with forging, casting or stamping; one of the main reasons for using cnc lathe turning to process precision stainless steel parts is that the processing cost is negligible or none.

4.Cnc horizontal lathe is widely known for its high efficiency and fast production time. The machining of stainless steel enables the production of high volumes of machined parts with greater precision in less time.

5.Automatic cnc lathe can make more complex stainless steel parts.

Applications of automatic cnc lathe include:

1.High precision cnc lathe can process fasteners such as bolts and screws;

2. The flat bed cnc lathe machine can process household items such as furniture legs, decorative fixtures and cooking utensils;

3. Cnc lathe machine can process auto parts, such as bearings, wheels and crankshafts;

4. Cnc lathe can process medical equipment, such as surgical tools or prosthetics made of advanced materials;

5.Mini cnc lathe machine can process aerospace parts, such as engine parts or landing gear parts.

Video

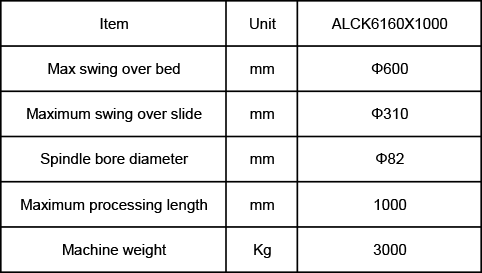

Product Parameters