PRODUCT

5-axis vertical machining center ALVMC1370

With the continuous development of industrial technology, the functions and performance of machining centers are increasingly enhanced, bringing broader application prospects to all walks of life. 5-axis vertical machining center ALVMC1370, as a high-tech product, leads the innovation in the machining field. This article will deeply discuss the characteristics of ALVMC1370 large CNC milling machine and its application in many industries.

The 5-axis vertical machining center ALVMC1370 is widely used in aerospace, mold manufacturing, vehicle manufacturing, shipbuilding, medical equipment and other industries due to its multi-axis linkage, high performance and large worktable. Its efficient and precise processing capabilities inject new vitality into industrial manufacturing and help all walks of life to achieve efficient and high-quality production. With the continuous advancement of science and technology, ALVMC1370 vertical machining center will continue to expand the processing field and bring more possibilities for industrial manufacturing.

Main features of 5-axis vertical machining center ALVMC1370:

1. Multi-axis linkage: ALVMC1370 large-scale CNC milling machine adopts 5-axis linkage technology, that is, the linkage control of the three linear axes of X, Y, and Z and the two rotary axes of A, C. This configuration enables it to realize multi-angle machining of complex parts, improving machining accuracy and flexibility.

2. High-performance spindle: ALVMC1370 heavy-duty CNC milling machine is equipped with a high-performance spindle, which has the characteristics of high speed, high power and high rigidity. The fast rotation and high torque output of the spindle ensure high-efficiency cutting and processing results.

3. Large workbench: ALVMC1370 large vertical machining center has a spacious workbench area, which is suitable for processing large parts and workpieces with complex shapes. The large worktable provides a larger processing space to meet the processing needs of workpieces of different sizes.

4. High-precision measurement system: ALVMC1370 vertical machining center is equipped with a high-precision measurement system, which can monitor the processing status and accuracy of the workpiece in real time, and perform automatic compensation to ensure the processing quality.

5. Automatic tool change system: ALVMC1370 vertical machining center is equipped with an intelligent automatic tool change system, which realizes automatic change of various tools and greatly improves production efficiency and automation level.

Application of 5-axis vertical machining center ALVMC1370 in multiple industries:

1. Aerospace: In the field of aerospace, ALVMC1370 vertical machining centers are widely used in the processing of complex structural parts and parts, such as engine parts, aircraft structural parts, etc. The 5-axis linkage technology enables it to complete the machining of multiple surfaces within one clamping, improving machining accuracy and efficiency.

2. Mold manufacturing: In the mold manufacturing industry, ALVMC1370 CNC milling machine is widely used. The vertical machining center can efficiently process all kinds of molds, including plastic injection molds, die-casting molds, forging molds, etc. 5-axis linkage technology and high-performance spindle guarantee the high precision and surface quality of the mold.

3. Vehicle manufacturing: In the automobile manufacturing industry, ALVMC1370 CNC milling machine can be used to process complex workpieces such as automobile chassis, engine parts, body structural parts, etc., to meet the high-precision processing requirements of automobile manufacturing.

4. Shipbuilding: In the shipbuilding industry, the large table area and 5-axis linkage technology of the ALVMC1370 large-scale CNC milling machine enable it to process large-scale ship structural parts and components, and improve the efficiency and precision of shipbuilding.

5. Medical devices: In the field of medical device manufacturing, ALVMC1370 large-scale 5-axis CNC milling machine can be used to process complex medical device parts, such as artificial joints, medical devices, etc., to meet the high requirements of medical device manufacturing.

Machine standard and optional:

(1) Resin sand castings, tempered and aged.

(2) Taiwan Shangyin ball screw and precision screw lock nut;

(3) Taiwan Silver Roller Linear Guide

(4) Taiwan BT40 spindle unit (8000 rpm).

(5) Taiwan supporting booster cylinder and synchronous pulley.

(6) Imported NTN bearings for screw rods

(7) Inner protection of X, Y, Z three-axis stainless steel guide rails

(8) Equipped with automatic lubricating system, cooling, spindle air blowing, warning lights, explosion-proof lighting, etc.

(9) The standard configuration is full metal outer protection, and the economical half protection is optional.

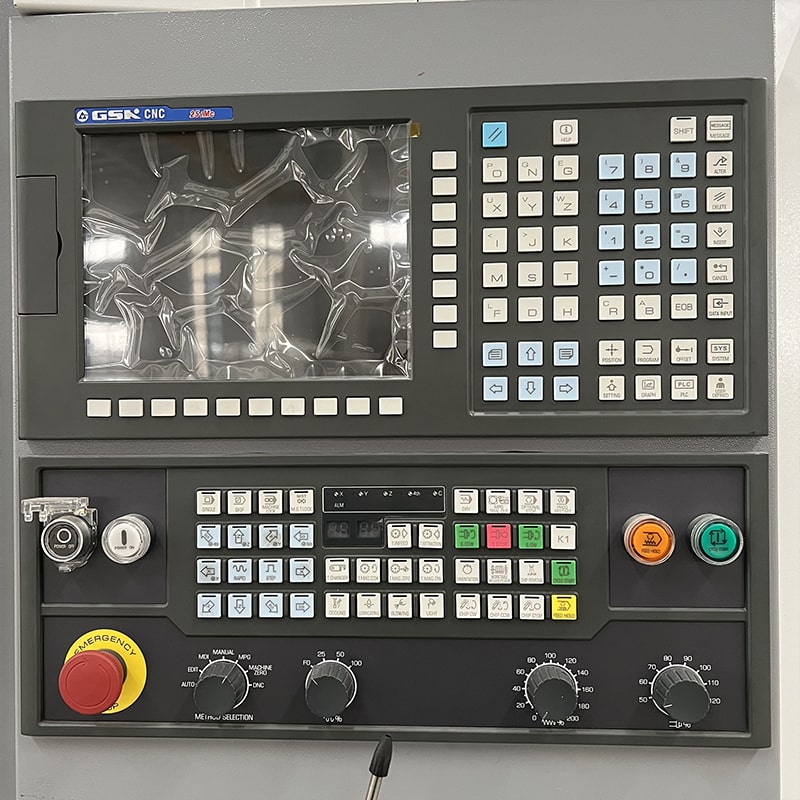

(10) The system is equipped with a wide digital bus system as standard, and supports optional four-axis.

(11) Choose to configure the new generation,KND, Fanuc, Siemens, Mitsubishi and other systems.