PRODUCT

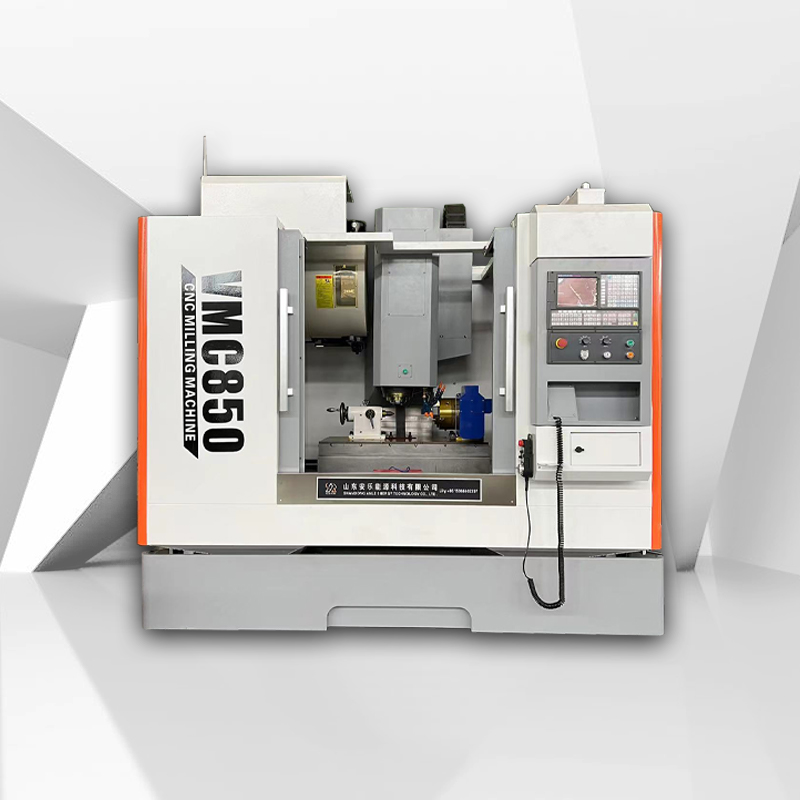

4-axis vertical machining center ALVMC850

In modern manufacturing, high-precision and high-efficiency processing equipment is crucial to improving production efficiency. ALVMC850 four-axis vertical machining center is a multi-functional equipment with excellent performance and a wide range of applications. This article will introduce the characteristics of ALVMC850 CNC milling machine and its application in many industries.

Through the excellent features and wide application of ALVMC850 four-axis vertical machining center, CNC milling machine has become a processing tool in many industries. Whether it is automobile, aerospace, electronic equipment or general machinery manufacturing and shipbuilding, ALVMC850 CNC milling machine can provide high-precision and high-efficiency processing solutions to help enterprises improve production efficiency and product quality. We believe that ALVMC850 4-axis CNC milling machine will play an important role in many industries and promote the development and progress of industrial manufacturing.

Features of ALVMC850 four-axis vertical machining center:

1. Multi-axis processing capability: ALVMC850 small CNC milling machine adopts four-axis design, with rotary table and spindle rotation function, which can realize multi-axis processing and greatly improve the flexibility and efficiency of processing.

2. High-precision machining: The machining center adopts high-precision linear guide rail and spindle system, which has excellent machining accuracy and stability, and is suitable for machining workpieces with high precision requirements.

3. Multifunctional tool magazine: ALVMC850 CNC machining center is equipped with a multifunctional tool magazine, which can accommodate a variety of cutting tools, realize automatic tool switching and multi-process processing, and greatly improve processing efficiency.

4. User-friendly operation interface: The equipment is equipped with an intuitive and easy-to-understand CNC operation interface and an intelligent control system, which is easy to operate and reduces the operator's technical requirements and learning costs.

5. High rigid structure design: The machining center adopts a high rigid body structure design, which can maintain stability during high-speed cutting and ensure processing quality and workpiece accuracy.

Applications of ALVMC850 in multiple industries:

1. Auto parts manufacturing: ALVMC850 CNC milling machine can be used to process various auto parts, such as engine block, chassis parts, transmission system parts, etc., providing high-precision and high-efficiency processing solutions for the automobile manufacturing industry.

2. Manufacturing of aerospace parts: In the field of aerospace, the ALVMC850 vertical machining center can be used to process complex aerospace structural parts, aero-engine parts, etc., to meet the requirements of high precision and high reliability.

3. Electronic equipment manufacturing: The machining center can be used to process precision parts such as housings, radiators, and connectors of electronic equipment, meeting the high-precision and high-quality requirements of the electronic equipment manufacturing industry.

4. General machinery manufacturing: ALVMC850 4-axis CNC milling machine is suitable for general machinery manufacturing, such as mold manufacturing, industrial equipment manufacturing, etc., providing high-quality processing services for various industries.

5. Shipbuilding: The machining center can be used to process structural parts of ships, propulsion system components, etc., to meet the high precision and high efficiency requirements of the shipbuilding industry.

Machine standard and optional:

(1) Resin sand castings, tempered and aged.

(2) Taiwan Shangyin ball screw and precision screw lock nut;

(3) Taiwan Silver Roller Linear Guide

(4) Taiwan BT40 spindle unit (8000 rpm).

(5) Taiwan supporting booster cylinder and synchronous pulley.

(6) Imported NTN bearings for screw rods

(7) Inner protection of X, Y, Z three-axis stainless steel guide rails

(8) Equipped with automatic lubricating system, cooling, spindle air blowing, warning lights, explosion-proof lighting, etc.

(9) The standard configuration is full metal outer protection, and the economical half protection is optional.

(10) The system is equipped with a wide digital bus system as standard, and supports optional four-axis.

(11) Choose to configure the new generation,KND, Fanuc, Siemens, Mitsubishi and other systems.

Video

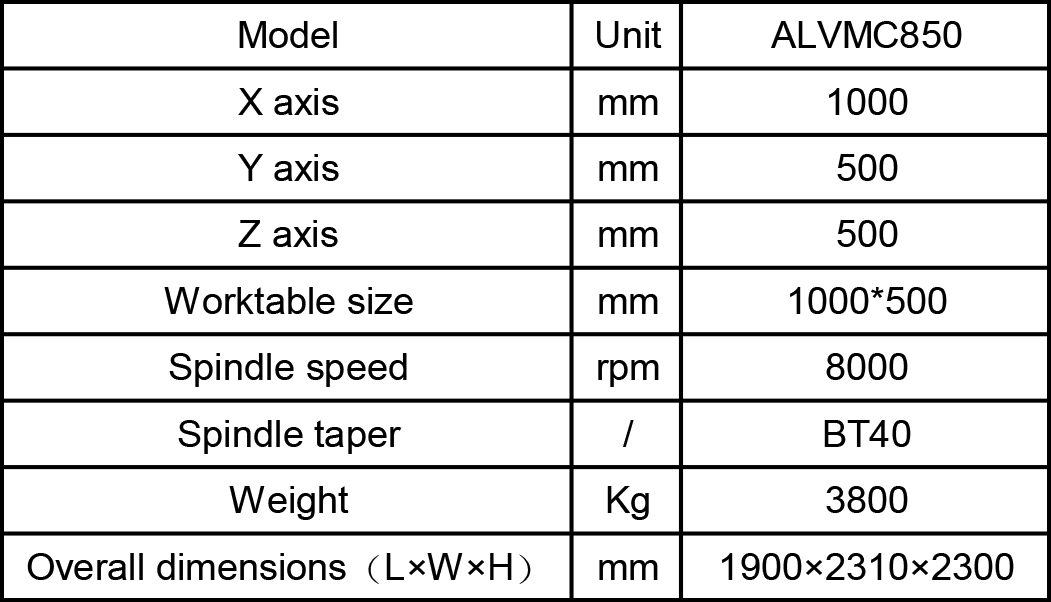

Technical Parameters