PRODUCT

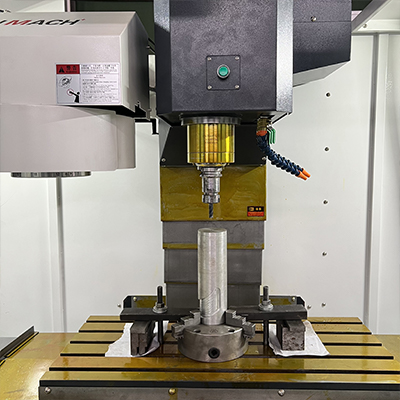

3 Axis Vertical Machining Center VMC650: Ideal for High Precision Machining and Wide Application

The 3-axis vertical machining center VMC650 is an advanced equipment with high-precision machining capabilities and wide applicability. This article will introduce the characteristics and application industries of VMC650 to demonstrate its important role in the field of industrial manufacturing.

The 3-axis vertical machining center VMC650 plays an important role in industries such as aerospace, automobile manufacturing, mold manufacturing and general machinery manufacturing due to its high-precision processing capability, multi-functional processing capability, high-efficiency production capacity and stable performance. It can meet the processing needs of complex parts, and help enterprises improve production efficiency and product quality through high-precision processing and high-efficiency production. The VMC650 vertical machining center is ideal for industrial manufacturing.

Machine standard and optional:

(1) Resin sand castings, tempered and aged.

(2) Taiwan Shangyin ball screw and precision screw lock nut;

(3) Taiwan Silver Roller Linear Guide

(4) Taiwan BT40 spindle unit (8000 rpm).

(5) Taiwan supporting booster cylinder and synchronous pulley.

(6) Imported NTN bearings for screw rods

(7) Inner protection of X, Y, Z three-axis stainless steel guide rails

(8) Equipped with automatic lubricating system, cooling, spindle air blowing, warning lights, explosion-proof lighting, etc.

(9) The standard configuration is full metal outer protection, and the economical half protection is optional.

(10) The system is equipped with a wide digital bus system as standard, and supports optional four-axis.

(11) Choose to configure the new generation,KND, Fanuc, Siemens, Mitsubishi and other systems.

Features of CNC milling machine:

1. High-precision machining capability: VMC650 vertical machining center adopts advanced numerical control technology and high-precision transmission system, which has excellent machining accuracy. The CNC milling machine can maintain the accuracy and surface quality of the workpiece size and meet the processing tasks that require high precision.

2. Multifunctional processing capability: VMC650 vertical machining center has various processing functions, including milling, drilling, boring and other operations. CNC milling machines can adapt to the processing needs of various complex parts and provide flexible and diverse processing options.

3. Efficient production capacity: The equipment is equipped with high-speed spindle and feeding system to achieve fast processing speed and efficient production capacity. Whether it is batch production or small batch multi-variety processing needs, VMC650 can provide high-efficiency production solutions.

4. Advanced numerical control system: VMC650 vertical machining center is equipped with advanced numerical control system, with friendly man-machine interface and rich processing control functions. Operators can easily program and operate, realizing efficient production control and process management.

5. Stable performance: VMC650 vertical machining center has stable and reliable performance, can run stably for a long time, and maintain the consistency of high-precision machining. The solid construction and high-quality components of the CNC milling machine guarantee a stable and reliable machining process.

Application industry:

The VMC650 vertical machining center is widely used in many industries, including aerospace, automobile manufacturing, mold manufacturing, general machinery manufacturing, etc. VMC650 vertical machining center can be used to process various complex parts, such as aero engine parts, automobile engine parts, mold parts, etc.

Video

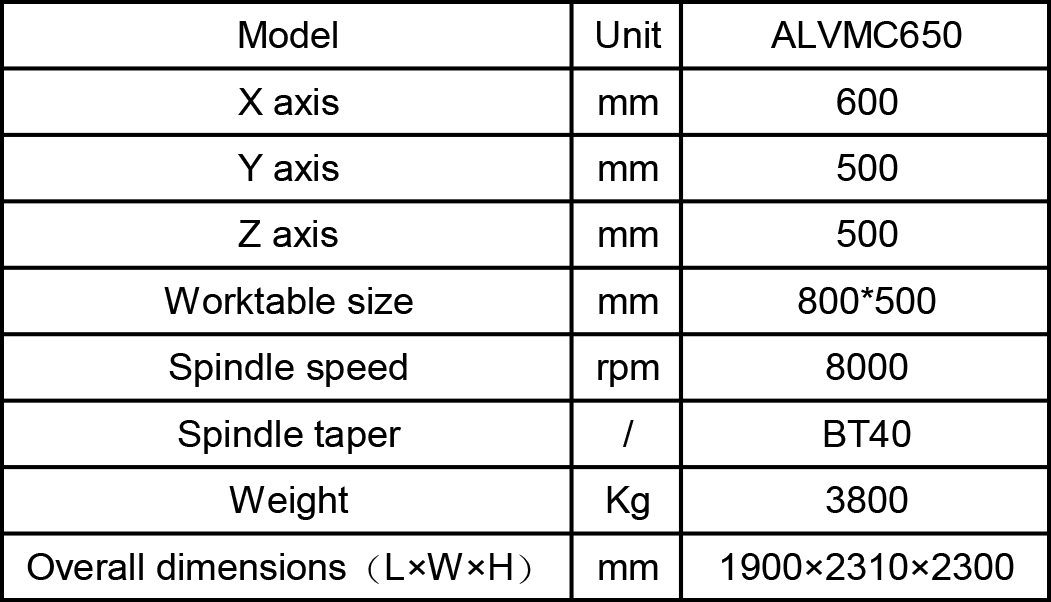

Technical Parameters