PRODUCT

ALTCK52DY CNC Turning and Milling Machine

ALTCK52DY CNC turning and milling compound machine tool is a high-performance equipment integrating turning and milling functions. This article will introduce the characteristics and application industries of ALTCK52DY, and at the same time outline its standard and optional configurations to demonstrate its important role in the field of industrial manufacturing.

ALTCK52DY CNC turning-milling compound machine tool is widely used in aerospace, automobile manufacturing, general machinery manufacturing and other industries due to its perfect combination of turning and milling functions, high-precision processing capability, high-efficiency production capacity and stable performance. By selecting suitable optional configurations, the processing efficiency and processing quality can be further improved to meet the customized processing needs of different industries.

Features of ALTCK52DY CNC turning and milling machine:

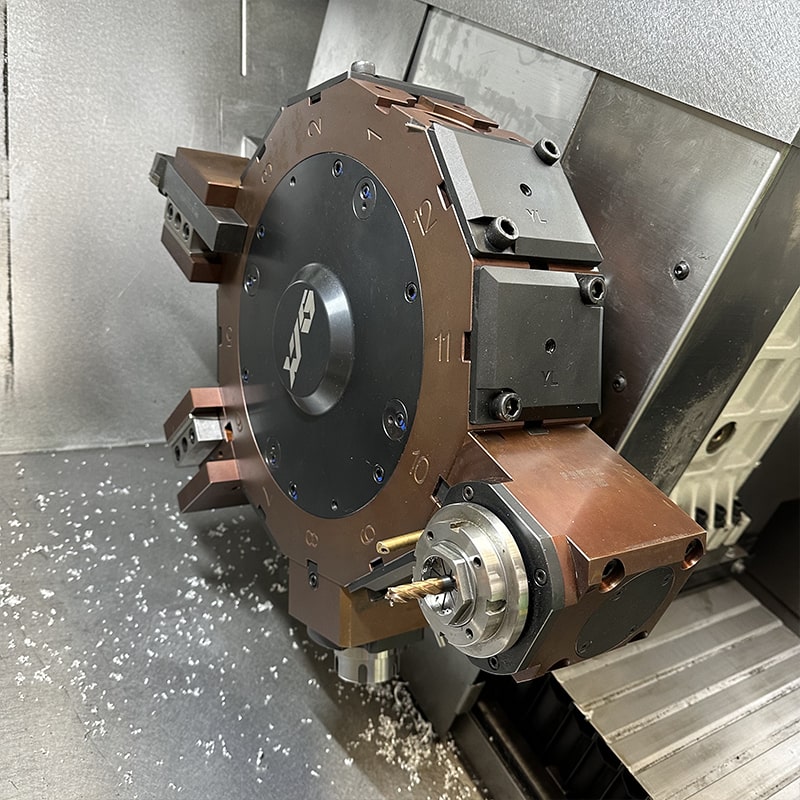

1. Perfect combination of turning and milling functions: ALTCK52DY CNC turning and milling compound machine tool integrates turning and milling functions, and realizes various processing operations through one device, including turning, milling, drilling, etc. It can adapt to the processing needs of various complex parts and provide flexible and diverse processing options.

2. High-precision machining capability: ALTCK52DY adopts advanced numerical control technology and precision transmission system, which has excellent machining accuracy. It can maintain the accuracy of part size and surface quality, and meet the processing tasks that require high precision.

3. Efficient production capacity: The equipment is equipped with high-speed spindle and feeding system to achieve fast processing speed and efficient production capacity. Whether it is batch production or small batch multi-variety processing needs, ALTCK52DY can provide high-efficiency production solutions.

4. Advanced CNC system: ALTCK52DY CNC turning and milling compound machine tool is equipped with advanced CNC system, with friendly man-machine interface and rich processing control functions. Operators can easily program and operate, realizing efficient production control and process management.

5. Stable performance: ALTCK52DY CNC turning and milling compound machine tool has stable and reliable performance, can run stably for a long time, and maintain the consistency of high-precision processing. Its rigid structure and high-quality components guarantee stable and reliable machining processes.

Application industry:

ALTCK52DY CNC turning and milling compound machine tool is widely used in many industries, including aerospace, automobile manufacturing, general machinery manufacturing, etc. CNC turning and milling machines can be used to process complex parts, such as aero engine parts, automotive engine parts, industrial machinery parts, etc.

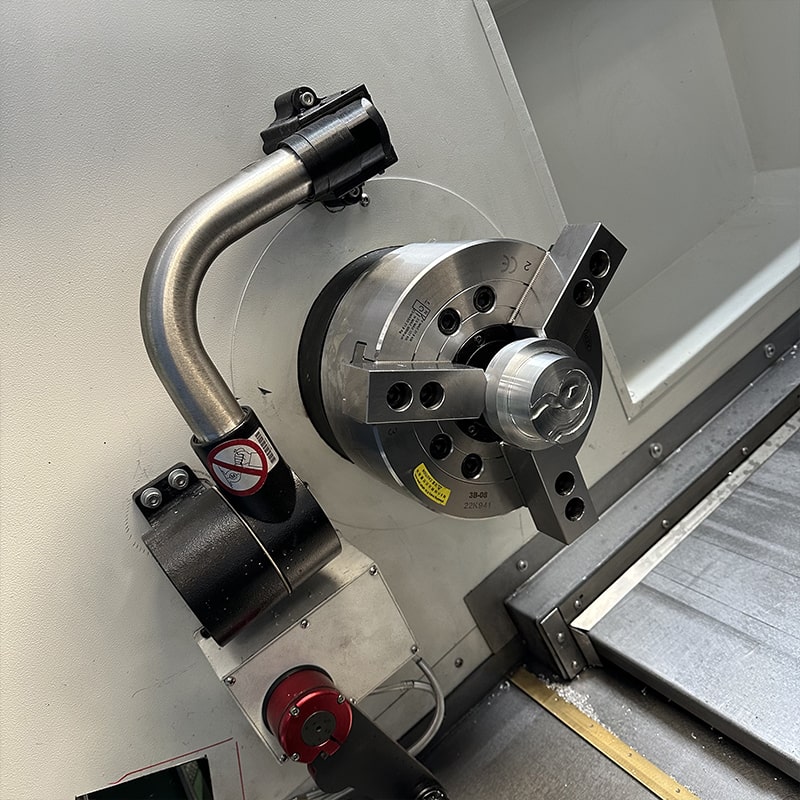

Standard configuration of CNC turning and milling machine ALTCK52DY:

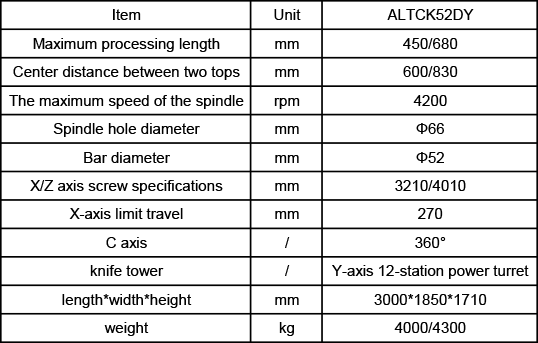

The standard configuration includes high-precision spindle, numerical control system, feed system, automatic lubrication system, workpiece clamping device, etc. These standard configurations guarantee the basic functions and processing performance of ALTCK52DY.

In terms of optional configuration, according to the needs of customers, the following configurations can be selected:

1. Automatic tool change system: Equipped with an automatic tool change device to achieve fast and accurate tool change, improving production efficiency and processing flexibility.

2. Automatic workpiece measurement system: Equipped with an automatic measuring device, it can measure the size and shape of the workpiece in real time, provide timely feedback and adjustment, and ensure the stability of processing quality.

3. Automatic loading and unloading system: realize automatic workpiece loading and unloading, improve production efficiency and operation convenience.

4. Processing process detection system: Equipped with processing process monitoring device, it can monitor tool wear and workpiece deformation in real time, provide real-time feedback and adjustment, and ensure the stability of processing quality.

Video

Technical Parameters