PRODUCT

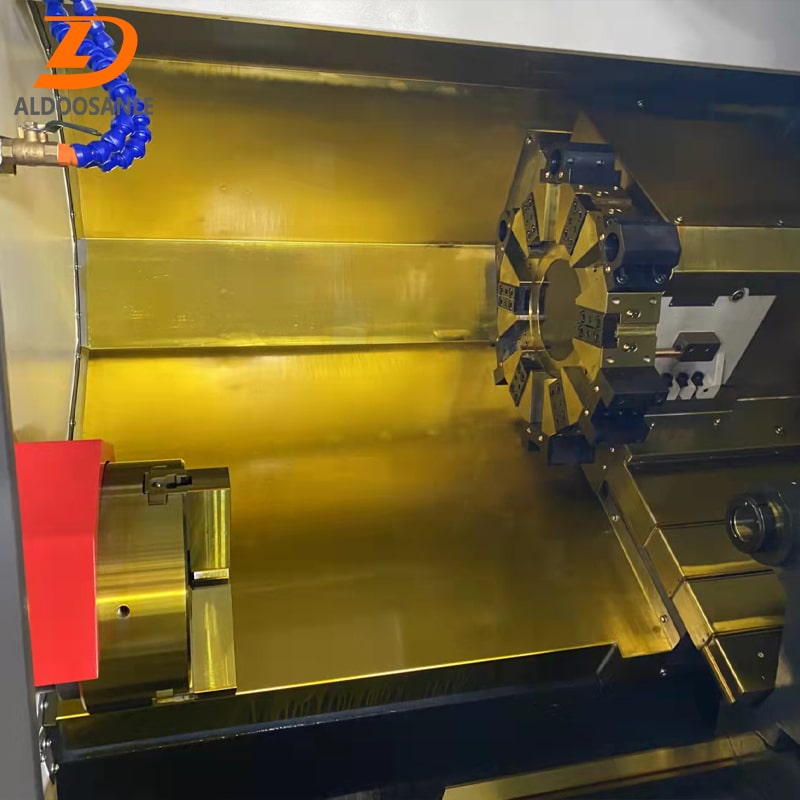

Slant Bed ALTCK66A horizontal cnc lathe

ALTCK66A of aldoosanlecnc is a one-piece cast metal cnc lathe with inclined bed, which can process straight cylinders, inclined cylinders, arcs and various threads.

The cnc lathe machine has high rigidity and high precision in manufacturing and tool setting. It can easily and accurately enter manual modification and automatic modification, so it can process parts with required dimensional accuracy.

CNC lathe machining can also process parts with high rigidity, high manufacturing precision, and shape accuracy requiring straightness, roundness, and cylindricity of the busbar. In the case of circular arcs and other curvilinear profiles, the machined shape is closer to the geometry required by the drawings than on a profiling lathe.

Product features of aldoosanlecnc

1.Higher accuracy Taiwan linear guideways

2.Higher speed spindle unit,Optional homemade spindle

3.Higher rigidity cast iron

4.Integrated automatic lubrication

5.One-piece Casting slant bed CNC lathe

How to maintain cnc lathe turning?

The daily maintenance and tumbling of cnc lathe tool holder is to prolong the service life of milling machine parts, prolong the replacement cycle of mechanical parts, prevent accidents, keep the machine in good condition all the time, and can work stably for a long time.

Different types of cnc lathe processing have different content and requirements for daily maintenance, and machine tool specifications are also clearly stipulated, but in general, they mainly include the following aspects:

(1) Regularly clean the working environment of the mini cnc lathe machine.

If the environment around the cnc lathe fanuc is too dirty and there is too much dust, it will affect the normal operation of the horizontal cnc lathe. If the circuit is too dirty, it may cause a short circuit. If the oil-water filter and the entire filter screen are too dirty, it will cause insufficient pressure and poor heat dissipation. and malfunctions, so regular cleaning is required.

(2) Keep the mini cnc lathe in a good lubrication state

Regularly check, clean the automatic lubrication system, add or replace grease and oil, so that the screw guide rail and other moving parts are always in a good lubrication state to reduce the mechanical wear rate.

(3) Check and adjust the high precision cnc lathe rack accuracy

Reduce positional deviation between switches and moving parts, including inspection and adjustment of switch systems, worktable switching systems, lead screws, and occurrence of reverse instability.

Video

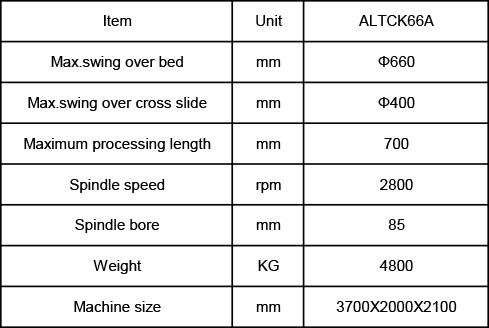

Product Parameters