PRODUCT

Aldoosanlecnc QK1327 CNC pipe threading lathe not only has the function of CNC lathe, but also can cut metric system, inch system cylinder, tapered pipe thread, etc., and has played a great role in the field of petroleum equipment.

Product Features

1. The CNC pipe threading lathe has an integrated modular design of machine, electricity and hydraulics, with reasonable layout and structure, comfortable operation and convenient maintenance.

2.CNC pipe thread lathe adopts horizontal bed, resin sand casting technology, wide guide surface, high overall rigidity, high speed and high precision

3. The sliding part of the cnc lathe pipe thread lathe machine has an automatic lubricating device.

4.CNC Oil Lathe two-jaw chuck, double chuck structure at the front and rear of the main shaft, convenient and reliable loading and unloading, can divide materials, reduce labor intensity.

5. The screw rod of the CNC turning machine, the guide rail adopts a centralized quantitative automatic lubrication device, the lubrication is sufficient and reliable, and the lubrication cycle is automatically controlled.

6. High quality cnc lathe automatic cooling chip removal system: The machine tool adopts the form of full guide rail protection, which is convenient for rear discharge. The main cooling box is divided into separate cases to ensure that the machine tool structure is not affected by cutting and pulling. The cooling pump with large flow and high head can be A strong cutting-to-clean and cooling effect is obtained. During the turning process, the workpiece and the tool are fully cooled, which ensures the machining accuracy of the workpiece and improves the service life of the tool.

7. The Automatic CNC Pipe Threading Machine has no water leakage, oil leakage, abnormal noise, fully enclosed protection, machine-water separation design, easy to use, operation, maintenance, beautiful appearance, and excellent after-sales service.

8. The measurement units of all parts and various instruments of CNC oil pipe lathe adopt international standards.

Application of CNC pipe threading lathe

The cnc lathe pipe thread lathe machine is suitable for processing various pipe joint parts, oil casing parts, drill pipe joints and various large diameter, super long and only need to process one end of various parts.

CNC turning machine can complete the turning of outer circle, inner hole and various threads, arcs, cones and rotary inner and outer surfaces.

Automatic CNC Pipe Threading Machine is suitable for high-efficiency, high-volume and high-precision machining of oil casings, drill pipe joints and other ultra-long rotating parts in the dry oil industry.

Video

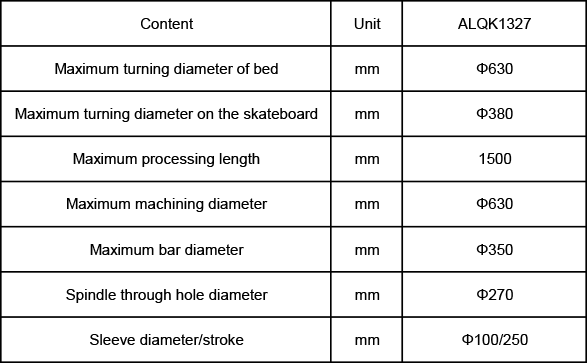

Technical Parameters